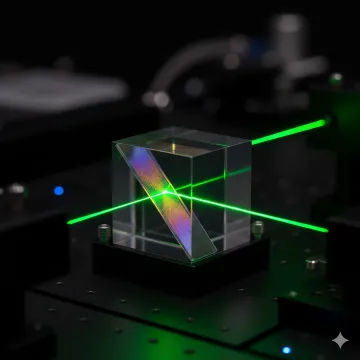

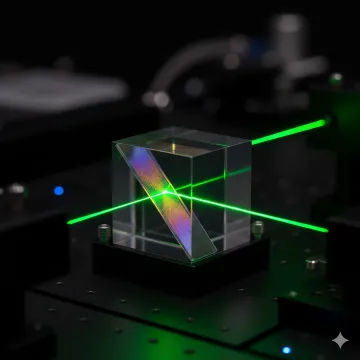

Diffractive Optical Elements

- 97-99% diffraction efficiency

- 1.5nm RMS surface finish

- Lightweight optical elements

ISO 13485-2016

Apollo Optical Systems specializes in custom IR imaging optics and precision optical components for demanding applications. Our advanced manufacturing capabilities include single-point diamond turning, polymer injection molding, and custom optical coatings. We serve medical devices, aerospace, automotive, and defense industries with lightweight, cost-effective optical solutions that reduce system complexity while maintaining superior performance standards.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 10 results

What materials can Apollo Optical Systems work with for IR imaging optics?

We work with PMMA, polycarbonate, polystyrene, cyclic olefin polymers, and various metals including nickel, brass, copper, and aluminum for custom IR optics.

What manufacturing methods does Apollo use for custom optical components?

What surface finish quality can Apollo achieve for IR imaging applications?

Does Apollo Optical Systems provide coating services for IR optics?

What size range can Apollo manufacture for custom IR imaging components?

What quality certifications does Apollo Optical Systems maintain?

How quickly can Apollo deliver custom IR imaging optics prototypes?

Talk to our experts for custom solutions and tailored guidance.

Custom IR optics for endoscopes, diagnostic equipment, and medical sensing applications with FDA-compliant materials.

Lightweight precision optics for night vision, guidance systems, and tactical applications requiring extreme reliability.

IR imaging optics for ADAS systems, LIDAR applications, and automotive lighting with demanding environmental specs.

Miniaturized IR optics for smartphones, AR/VR displays, and consumer imaging devices requiring cost-effective solutions.

Talk to our experts for custom solutions and tailored guidance.

Over 20 years of experience in single-point diamond turning and polymer injection molding with nanometer-level surface finishes for critical applications.

From initial design to high-volume production, we provide complete optical engineering, prototyping, coating, and testing services under one roof.

ISO 13485-2016 certified with comprehensive metrology and testing capabilities ensuring consistent performance for demanding medical and defense applications.

Connect with our optical engineering experts to discuss your specific requirements and receive a detailed quote within 24 hours.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com