One micron of coating failure can compromise an entire optical system and millions in product value.

Your choice of an optical coating partner will ultimately determine whether your product delivers measurable performance or becomes a liability in the field. The global optical coating market is projected to reach approximately USD 23.86 billion by 2026, fueled by rising demand for high-precision optics in ADAS, LiDAR, medical imaging, aerospace sensors, and advanced electronics.

Yet growth hasn’t eliminated core challenges. Manufacturers continue to struggle with coating uniformity at scale, rising raw material costs, and durability failures that shorten product life cycles, all of which directly impact yield and time-to-market.

This is why understanding the top optical coating companies matters. In this blog, we will discuss leading providers, evaluation criteria, and the capabilities that define long-term, scalable partnerships.

Key Takeaways

Optical coating performance directly impacts system accuracy, durability, yield, and time-to-market.

Not all top optical coating companies can scale reliably from prototype to high-volume production.

In-house metrology, DFM support, and material expertise are stronger predictors of success than coating type alone.

Polymer optics demand specialized coating stacks and process control; general coating vendors often fall short.

Vertically integrated partners like Apollo Optical Systems reduce risk by combining design, coating, inspection, and production under one roof.

What Are Optical Coatings?

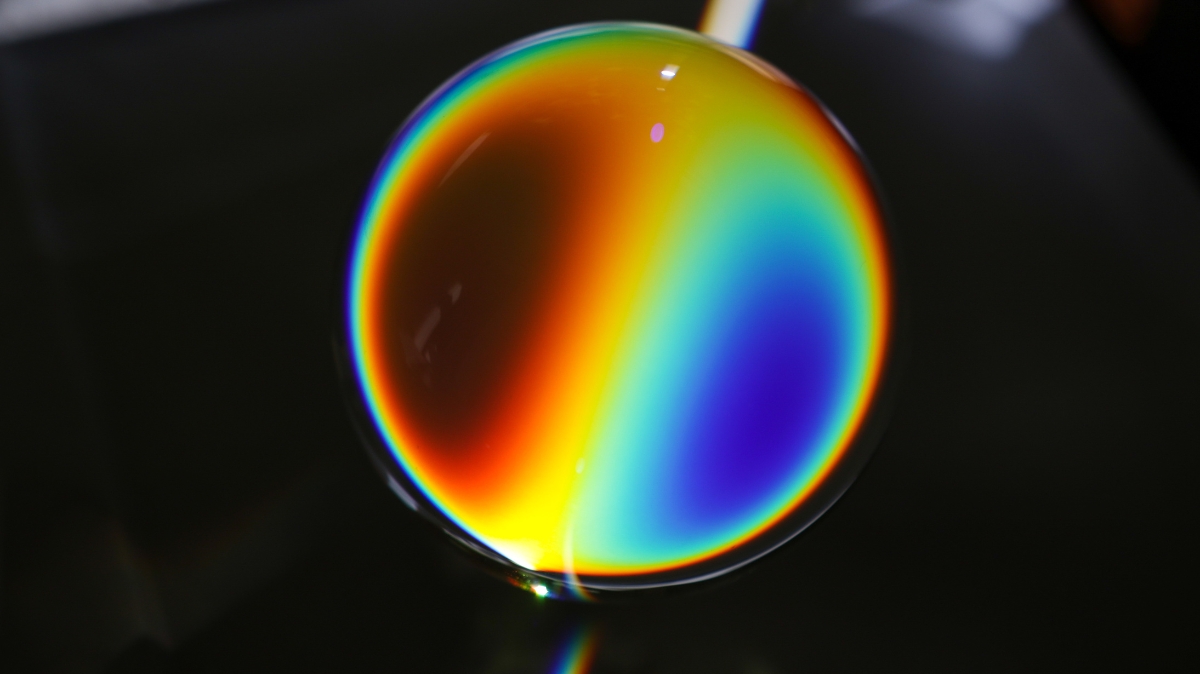

Optical coatings are engineered thin-film layers applied to optical surfaces, such as lenses, windows, mirrors, and filters, to control how light behaves. These coatings directly influence reflection, transmission, absorption, durability, and environmental stability of an optical system.

At a functional level, optical coatings are designed to:

Reduce unwanted reflections that cause glare, signal loss, or ghost images

Increase light transmission efficiency to improve image brightness and sensor accuracy

Control specific wavelength bands for filtering, sensing, or laser applications

Protect optical surfaces from abrasion, moisture, chemicals, and temperature extremes

Even a small deviation in coating thickness, measured in nanometers, can shift spectral performance enough to degrade system output.

Optical coatings are not single layers. They are typically multi-layer stacks, where each layer has a precisely controlled thickness and refractive index. These stacks are designed using optical modeling software and deposited using controlled vacuum-based processes.

In Apollo optical systems, these materials are deposited via evaporative thin‑film processes inside vacuum chambers, using custom fixturing for plastic and glass substrates from 2.5 mm to 150 mm and beyond.

Once you understand how optical coatings control light, the next step is knowing which coating type solves which real-world problem.

Core Optical Coating Types You’ll Encounter

Not all optical coatings solve the same problem. Each coating type is engineered to address a specific performance requirement, whether that’s maximizing light transmission, controlling reflection, protecting surfaces, or isolating precise wavelengths.

Below is a practical breakdown of the most commonly used optical coatings and the real-world scenarios where each one delivers value.

1. Anti-Reflective (AR) Coatings

AR coatings reduce surface reflections and increase light transmission by using precisely tuned thin-film layers. They are essential in applications such as medical imaging, cameras, and display optics, where higher transmission directly improves image clarity and sensor accuracy.

2. High-Reflective (HR) Coatings

HR coatings are designed to reflect nearly all incident light at specific wavelengths. They are commonly used in mirrors, laser cavities, and beam-steering optics where energy efficiency and wavelength stability are critical.

3. Protective Optical Coatings

Protective coatings improve resistance to abrasion, moisture, chemicals, and temperature fluctuations. These are widely used in automotive sensors, industrial optics, and defense systems exposed to harsh operating environments.

4. Narrowband Optical Filters

Narrowband coatings selectively transmit or block tightly defined wavelength ranges. They are critical in LiDAR, optical sensing, and spectroscopy applications that rely on precise spectral discrimination.

5. Broadband Optical Coatings

Broadband coatings maintain consistent optical performance across a wide wavelength range. They are typically used in imaging systems and optical assemblies that must perform reliably under varying lighting conditions.

Even the right coating type can fail if execution falls short.

Once optical systems move from design intent to real-world manufacturing, a new set of challenges emerges that directly affects yield, performance stability, and long-term reliability.

The Most Common Optical Coating Problems Companies Face

Optical coating problems rarely appear as obvious defects. More often, they show up as performance drift, inconsistent yields, or field failures, issues that are expensive to diagnose and even harder to correct at scale.

Below are the most common challenges companies face when sourcing or scaling optical coatings.

Inconsistent Coating Uniformity Across the Surface: Small thickness variations change transmission and color accuracy. Poor deposition control and weak fixturing lead to batch-to-batch performance inconsistency and higher scrap.

Adhesion Failures and Delamination: Inadequate surface prep or material mismatch causes coatings to peel under thermal or mechanical stress. This results in early failures and loss of qualification.

Durability Breakdowns in Real-World Environments: Coatings optimized only for lab performance degrade under UV, humidity, or abrasion. The result is shortened product life and rising ownership costs.

Wavelength Drift and Performance Variability: Loose thickness control causes filters to shift outside wavelength specs. This creates sensor inaccuracies and calibration failures.

Poor Scalability from Prototype to Production: Prototype-level coating processes often break at volume. Automation gaps increase costs, delays, and supply risk.

Material Cost and Supply Volatility: Specialty coating materials face pricing and supply instability. This disrupts margins and production planning.

Before shortlisting vendors, you need clear, technical criteria that go beyond marketing claims and focus on execution at scale.

Criteria to Evaluate Top Optical Coating Companies

Choosing the right optical coating partner is less about who offers the widest coating menu and more about who can consistently deliver performance, durability, and volume without surprises. Use the criteria below to evaluate vendors with precision.

1. Coating Process Control and Repeatability

A top provider must demonstrate tight control over coating thickness, uniformity, and run-to-run stability. Verify:

In-house process control and SPC (statistical process control)

Documented coating recipes tied to metrology data

Proven repeatability across multiple production batches

2. Substrate and Material Compatibility Expertise

Not all coatings behave the same on polymers, glass, or metals, especially under thermal or mechanical stress. Here verify:

Experience coating optical-grade polymers (e.g., acrylic, Zeonex, Ultem)

Ability to design coating stacks around substrate expansion properties

Material-specific adhesion validation

Material mismatch is the most common root cause of delamination and field failures.

3. Environmental and Durability Testing

Lab performance alone is not enough; coatings must survive real-world conditions.

Testing for humidity, abrasion, UV exposure, and thermal cycling

Qualification data tied to actual operating environments

Clear durability tradeoff discussions during design

Lack of durability testing shortens product life and increases warranty risk.

4. Scalability From Prototype to Production

Many suppliers can coat prototypes; few can scale reliably.

Ability to transfer SPDT or pilot coatings to automated production

High-volume equipment capacity and throughput

Proven ramp histories with similar part geometries

Scalability failures cause launch delays and unexpected cost spikes.

5. In-House Metrology and Inspection Capability

Top coating companies control quality through measurement, not assumptions. In-house metrology ensures performance stays within specification throughout production.

In-house thickness, reflectance, and transmission testing

Real-time or in-process monitoring

Traceable inspection and documentation

Strong metrology directly improves consistency, yield, and reliability.

6. Design-for-Manufacturability (DFM) Support

Effective coating partners engage early to optimize designs for yield, durability, and production efficiency before constraints are locked in.

Early collaboration during optical and mechanical design

Guidance on geometry, edge effects, and fixturing

Coating stacks optimized for manufacturability

Early DFM involvement prevents costly redesigns and late-stage failures.

7. Supply Chain Stability and Material Sourcing

Coating performance depends on consistent access to high-purity materials. Supply disruptions directly affect cost and delivery timelines.

Multiple qualified material suppliers

Controlled sourcing of high-purity inputs

Contingency plans for material shortages

A resilient supply chain protects margins and production schedules.

Once you know what separates a reliable coating partner from a risky one, the next step is applying those criteria to the market leaders that consistently deliver at scale.

Top 7 Optical Coating Companies for 2026

Below is a practical, buyer-focused overview highlighting what each company does best and where they are typically the strongest fit.

1. Apollo Optical Systems

Apollo Optical Systems specializes in precision optical coatings as part of a full end-to-end optics manufacturing ecosystem, including design, polymer injection molding, SPDT prototyping, metrology, assembly, and thin-film coatings for UV, visible, and NIR ranges.

Their coating services are engineered for performance and repeatability, especially on polymer substrates where thermal and adhesion challenges differ from glass.

Best fit for

OEMs needing single-source partners from design through production

Medical devices, automotive sensors, and defense imaging systems

Programs requiring polymer optics coated for performance and durability

2. Edmund Optics

Edmund Optics offers an extensive optical coating portfolio, including anti-reflection, highly-reflective, filter, polarizing, and high laser damage threshold (LDT) coatings across UV, visible, and IR spectral ranges. They pair this with state-of-the-art deposition (e.g., IBS, APS, e-beam) and metrology to ensure performance.

Best fit for

Precision optics needing custom thin-film solutions

High-power laser optics and imaging instruments

Systems requiring robust environmental and durability performance

3. II-VI Optical Systems (Coherent Corp.)

II-VI Optical Systems (now part of Coherent Corp.) provides advanced thin-film coatings for visible and infrared optics, including durable AR, high-efficiency AR, band-pass filters, and hard carbon coatings designed to withstand hostile environments. They combine coating design with fabrication, metrology, and high-volume production capabilities.

Best fit for

Aerospace, defense, and medical imaging systems

High durability and high-power optics applications

Complex IR and laser optical coatings

4. Zygo Corporation

Zygo’s optical coatings leverage its deep metrology and optical fabrication expertise, offering AR, reflective, and specialty coatings across broad wavelength ranges, from UV to MWIR. Their vertically integrated approach ensures substrate and coating performance are qualified together.

Best fit for

Ultra-precision optics and sensing subsystems

Applications where tight surface and spectral control are required

Defense, space, and high-end scientific instruments

5. Syntec Optics

Syntec Optics offers coating and full optical manufacturing as part of a vertically integrated service, covering design, replication, precision machining, and coatings on both polymer and glass optics. Their broad service mix supports several industries.

Best fit for

Polymer optics and photonics systems

Medical, defense, and consumer electronics applications

Programs needing both coating and assembly expertise

6. Optimax Systems

Optimax’s optical coating capabilities are part of its full manufacturing ecosystem, producing AR coatings, beamsplitters, metal mirrors, filters, and highly precise broadband and laser coatings for demanding applications, including space, defense, and high-power laser systems.

Best fit for

High precision, large-format optics (up to ~500 mm coatings)

Space, defense, semiconductor, and medical markets

Complex optical systems requiring integrated fabrication and coatings

7. Rochester Precision Optics (RPO)

RPO combines thin-film coatings with its strong heritage in precision glass molding, polymer optics, machining, and full assembly. Their IR broadband AR and diamond-like coatings are optimized for thermal imaging, sensing, and severe environmental conditions.

Best fit for

Infrared sensing and thermal imaging systems

Programs needing vertical integration from prototype to production

Defense and industrial applications requiring durable IR coatings

After reviewing leading optical coating providers, the real decision comes down to alignment, not reputation alone.

Which Optical Coating Company Is Right for Your Industry?

Different industries place very different demands on optical coatings. Use the guidance below to narrow your choice based on what actually matters for your application.

1. Medical Devices and Healthcare Optics

Medical optics must meet strict regulatory and performance standards, especially when coatings are applied to polymer substrates used in patient-facing or diagnostic devices. Key requirements:

ISO-certified quality systems (ISO 13485)

Strong coating adhesion on optical-grade polymers

Resistance to sterilization, moisture, and cleaning agents

Apollo Optical Systems stands out due to its ISO 13485 certification, polymer optics specialization, and in-house coating, metrology, and assembly, reducing validation risk and supplier handoffs.

2. Automotive, ADAS, and LiDAR Systems

Automotive optics operate in harsh environments and must scale reliably from prototypes to millions of parts. Key requirements

Coatings are stable under heat, vibration, and UV exposure

Tight wavelength and transmission consistency

High-volume, automated production capability

Apollo Optical Systems and Rochester Precision Optics (RPO) are strong fits due to their ability to transition SPDT prototypes into injection-molded, coated production optics.

3. Defense, Aerospace, and Tactical Systems

These applications demand coatings that perform reliably under extreme conditions while maintaining full traceability. Key requirements

Durable, reflective, IR, and protective coatings

Documented process control and change management

Proven experience in mission-critical programs

II-VI (Coherent), Zygo, and Optimax Systems are well-positioned due to their defense-grade coating capabilities and disciplined quality systems.

4. Industrial, Scientific, and Laser Applications

Precision and long-term stability are the primary drivers in industrial and scientific optics. Key requirements:

Tight thickness control and low wavelength drift

High laser damage threshold (LDT) coatings

Advanced in-house metrology

Zygo, Optimax Systems, and Edmund Optics offer the precision and inspection capabilities needed for long-life optical systems.

5. Consumer Electronics and Commercial Imaging

This segment prioritizes speed, cost efficiency, and repeatable quality over extreme customization. Key requirements:

Standardized coating processes

Fast turnaround and high mix capability

Consistent quality at volume

Edmund Optics and Syntec Optics are typically better aligned for consumer imaging and display applications.

6. Polymer-Based Optical Systems

Polymer optics introduces unique challenges that coating-only vendors often struggle to address. Key requirements:

Coating stacks designed for polymer thermal behavior

Strong adhesion and durability

Integrated molding and coating expertise

Apollo Optical Systems excels by designing coatings specifically for optical-grade polymers and controlling the entire manufacturing workflow.

The evolution of optical systems is forcing coatings to move beyond enhancement and into the role of performance-defining technology.

Emerging Trends Shaping Optical Coatings Beyond 2026

Optical coatings are entering a new phase of innovation, driven by rising demand for precision optics, lightweight systems, and long-term durability across industries. Key trends shaping optical coatings beyond 2026 include:

According to market research, the global optical coatings market is projected to grow robustly from about USD 11.5 billion in 2025 to USD 25.8 billion by 2035, at a strong ~8.4 % CAGR, indicating sustained demand across industries and devices that rely on precise light control.

Multi-functional coatings combining anti-reflective, scratch-resistant, UV, and hydrophobic properties are reducing part count and assembly complexity in optical systems.

Advanced deposition technologies such as ion-beam sputtering and atomic layer deposition (ALD) are enabling tighter thickness control and better uniformity on complex geometries.

Polymer-optimized coatings are gaining traction as lightweight optics replace glass in automotive and medical applications, requiring redesigned adhesion and thermal-management layers.

Stricter durability expectations are pushing manufacturers to validate coatings under real-world humidity, UV, abrasion, and thermal cycling rather than lab-only conditions.

Future-ready optical coating partners will be those that combine materials science, process control, and scalable manufacturing, moving coatings from a final step to a core design and performance enabler.

Once you’ve seen how coating technology is evolving and how to evaluate partners, it’s time to look at a real partner that meets those criteria and can actually execute from design through full-scale coated production.

Partner with Apollo Optical Systems to Achieve Reliable Optical Coating Performance

Apollo Optical Systems is a precision optics design and manufacturing company specializing in polymer and glass optical components with integrated coating, metrology, and assembly capabilities.

This means they don’t just apply coatings, they engineer them in context with the entire optical system to ensure performance, durability, and manufacturing scalability.

At its core, Apollo:

Designs and engineers optics with performance and manufacturability in mind, rather than treating coatings as an afterthought.

Executes precision polymer injection molding and SPDT prototyping, enabling smooth transition from prototype to production.

Delivers advanced thin-film optical coatings, including anti-reflective (AR), mirror, filter, and custom solutions for UV, visible, and NIR applications on both plastic and glass.

Performs in-house metrology and testing, ensuring coatings meet tight spectral and environmental criteria.

Ready to bring your optical coating project to production?

Contact Apollo Optical Systems to discuss custom coating strategies that align with your performance, manufacturability, and scale requirements, and see how integrated design + coating can accelerate your product roadmap.

Summing Up,

Optical coatings directly influence system accuracy, durability, and long-term reliability, and the difference between success and failure often comes down to who applies them and how.

As applications become more demanding across medical, automotive, defense, and sensing systems, companies need partners that can engineer coatings in context, control them in production, and scale without performance drift.

Apollo Optical Systems stands out by combining optical design, polymer expertise, in-house coating, metrology, and ISO-certified manufacturing under one roof, reducing risk, complexity, and time-to-market while delivering consistent, production-ready results.

If your optical system requires coatings that perform reliably from prototype through high-volume production, partner with Apollo Optical Systems to design, coat, measure, and scale with confidence.

FAQs

1. What do optical coatings do in optical systems?

Optical coatings control how light interacts with a surface by reducing reflection, increasing transmission, enhancing reflectivity, or protecting optics from environmental damage.

2. How do I choose the right optical coating company?

Look for proven industry experience, in-house metrology, scalability from prototype to production, material expertise (especially polymers), and relevant certifications like ISO 13485.

3. Why do optical coatings fail over time?

Common causes include poor adhesion, thermal expansion mismatch, inadequate environmental testing, and inconsistent thickness control during production.

4. Are optical coatings different for glass and polymer optics?

Yes. Polymer optics require specialized coating stacks and surface preparation to address adhesion, thermal sensitivity, and durability challenges.

5. Can one optical coating partner support both prototyping and mass production?

Only vertically integrated providers with design-for-manufacturability processes and automated coating capabilities can reliably scale from prototype to high-volume production.