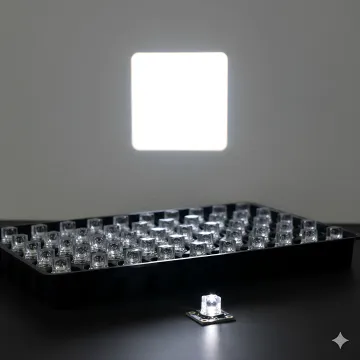

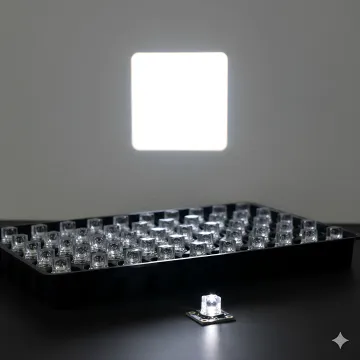

Precision Polymer Microscope Objective Lenses

- Tight manufacturing tolerances

- Lightweight polymer construction

- Biocompatible materials

ISO 13485-2016 Certified

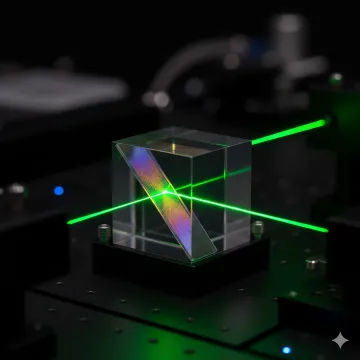

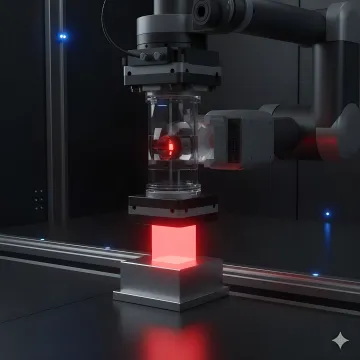

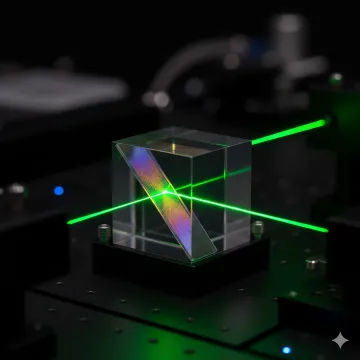

Comprehensive ophthalmology and optical medical devices including precision polymer microscope objective lenses, refractive optical elements, freeform lenses, optical windows, and beam splitters. Engineered for medical applications with ISO 13485-2016 certification, these devices serve endoscopes, diagnostic equipment, medical sensing, and surgical systems with exceptional optical performance and biocompatible materials.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 12 results

What medical applications are these optical devices designed for?

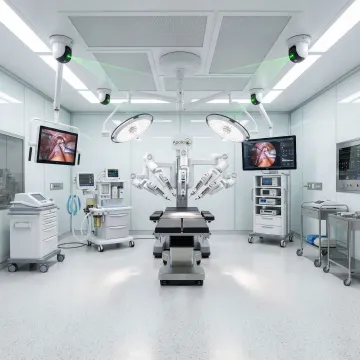

Our devices serve endoscopes, diagnostic equipment, medical sensing applications, pulse oximeters, photoplethysmography sensors, and robotic surgery systems with FDA-compliant materials.

Are these optical components biocompatible for medical use?

What manufacturing tolerances can you achieve for medical optics?

Do you provide custom optical design services for medical devices?

What quality certifications do you maintain for medical device manufacturing?

Can you manufacture both prototype and production volumes?

What optical coatings are available for medical applications?

Talk to our experts for custom solutions and tailored guidance.

Precision optical components for endoscopes, diagnostic equipment, and medical sensing applications requiring biocompatible materials.

Optical elements for robotic surgery systems, position tracking, and surgical imaging requiring exceptional precision and reliability.

High-performance optical windows and lenses for microscopy, imaging systems, and diagnostic equipment in clinical laboratories.

Optical sensing components for pulse oximeters, photoplethysmography sensors, and patient monitoring medical devices.

Talk to our experts for custom solutions and tailored guidance.

Medical device quality management certification ensures consistent manufacturing standards and regulatory compliance for critical healthcare applications.

Advanced single-point diamond turning and polymer injection molding capabilities deliver tight tolerances and superior optical performance consistently.

From design verification to metrology testing, comprehensive in-house capabilities accelerate development and ensure seamless project execution.

Connect with our optical engineers for technical consultation, custom design solutions, and rapid prototyping services.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at