Freeform Lenses

- 97-99% diffraction efficiency

- 1.5nm RMS surface finish precision

- Wide material compatibility

ISO 13485-2016 Medical Certified

Quality Manufacturing Excellence

Precision Optics Association

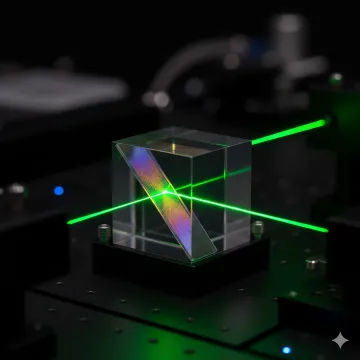

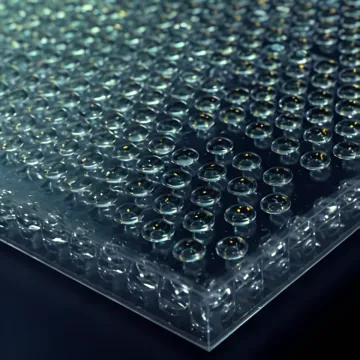

Explore precision-engineered acrylic lenses designed for optical and industrial applications. Apollo Optical Systems manufactures custom PMMA lenses, aspheric optics, and diffractive elements for medical devices, automotive systems, AR/VR displays, and lighting solutions. With ISO 13485-2016 certification and advanced polymer injection molding capabilities, we deliver lightweight, cost-effective alternatives to glass optics without compromising optical performance.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

What acrylic materials are available for custom lens manufacturing?

We manufacture lenses using PMMA (acrylic), polycarbonate, polystyrene, cyclic olefin polymers (COP/COC), and ULTEM. Material selection depends on optical requirements, chemical compatibility, and application environment.

What manufacturing methods does Apollo Optical Systems use for acrylic lenses?

Are your acrylic lenses suitable for medical device applications?

What size range can you manufacture for acrylic optical components?

What surface types and finishes are achievable with acrylic lenses?

Can you apply optical coatings to acrylic lenses?

What are the advantages of acrylic lenses over glass optics?

Talk to our experts for custom solutions and tailored guidance.

Precision acrylic lenses for endoscopes, diagnostic equipment, optical sensors, and surgical instruments meeting ISO 13485-2016 standards.

Lightweight acrylic optics for ADAS sensors, LIDAR windows, headlamps, interior lighting, and advanced driver assistance applications.

Custom freeform and aspheric acrylic lenses for virtual reality headsets, augmented reality displays, and head-mounted devices.

High-performance acrylic reflectors and lenses for aircraft reading lights, emergency lighting, and compound parabolic landing systems.

Talk to our experts for custom solutions and tailored guidance.

Rigorous quality management ensures every acrylic lens meets medical device standards with comprehensive documentation and traceability for critical applications.

21,000 sq. ft. facility features single-point diamond turning, polymer injection molding, precision coating, and in-house metrology for complete optical solutions.

Born from University of Rochester's Institute of Optics legacy, we deliver proven polymer optical solutions from prototype through high-volume production.

Connect with our optical engineering team for custom lens design, material selection guidance, and rapid prototyping. Expect detailed technical consultation within 24 hours.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com