Freeform Lenses

- 97-99% diffraction efficiency

- 1.5nm RMS surface finishes

- Lightweight large apertures

ISO 13485-2016 Medical Device Quality

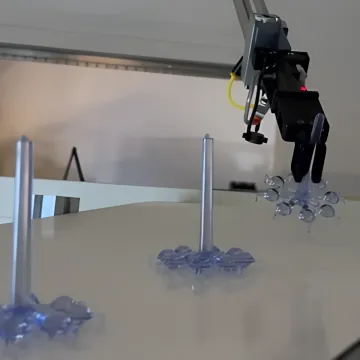

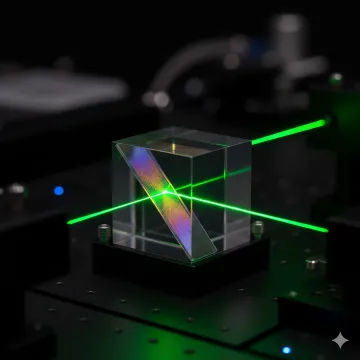

Custom optics solutions for precision manufacturing encompass advanced refractive, diffractive, and freeform optical elements engineered for medical devices, automotive systems, VR/AR displays, and aerospace applications. Apollo Optical Systems delivers lightweight, high-performance polymer and metal optics manufactured through injection molding and single-point diamond turning, achieving surface finishes down to 1.5 nanometers and tolerances within 0.002mm for applications demanding optical excellence.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

What tolerance levels can Apollo Optical Systems achieve in custom optics manufacturing?

We achieve tolerances down to 0.002mm concentricity, surface finishes of 1.5 nanometers RMS, and surface figures of <¼ wave peak-to-valley in metals and <½ wave in polymers.

What manufacturing methods does Apollo Optical Systems use for custom optical components?

Which industries benefit most from Apollo Optical Systems' custom optics solutions?

What materials can be used for custom optical element fabrication?

Does Apollo Optical Systems offer coating services for custom optics?

What is the typical size range for custom optical components?

How does Apollo Optical Systems ensure quality in custom optics manufacturing?

Talk to our experts for custom solutions and tailored guidance.

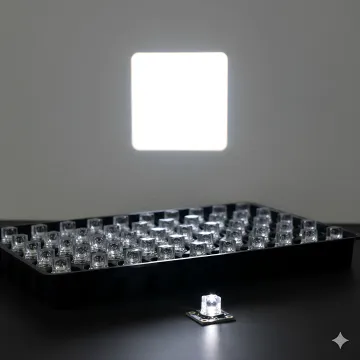

Precision polymer optics for endoscopes, microscope objectives, optical covers, pulse oximeters, and diagnostic equipment requiring biocompatible materials and tight tolerances.

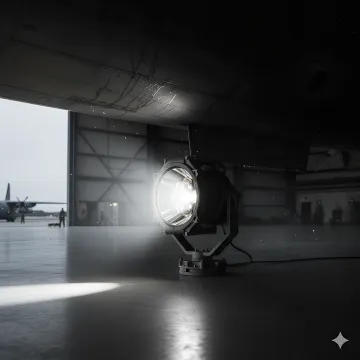

Lightweight optical systems for aircraft reading lights, emergency lighting, landing lights, tactical sights, night vision devices, and guidance systems meeting stringent performance requirements.

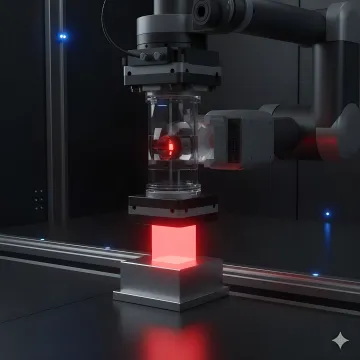

Advanced optics for LIDAR windows, automotive sensors, head and tail lighting systems, interior illumination, and emergency vehicle lighting with optimized light distribution.

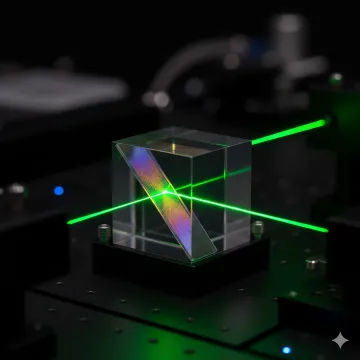

High-performance freeform lenses and aspheric optics for virtual reality headsets, augmented reality displays, smartphone cameras, and head-mounted display systems requiring lightweight construction.

Talk to our experts for custom solutions and tailored guidance.

From design verification to high-volume production, our 21,000 sq. ft. facility houses single-point diamond turning, injection molding, and advanced metrology capabilities for complete optical solutions.

Achieving surface finishes down to 1.5 nanometers and tolerances within 0.002mm, our ISO 13485-2016 certified processes ensure optical performance meets the most demanding specifications.

Since 2002, we've delivered precision polymer and metal optics for medical devices, aerospace systems, and defense applications, backed by expertise from the University of Rochester's Institute of Optics.

Connect with our optical design experts to discuss your precision optics requirements. Receive technical guidance, tolerance analysis, and a detailed quote within 48 hours.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com