Diffractive Optical Elements

- 97-99% diffraction efficiency

- 1.5nm RMS surface finishes

- Large aperture lightweight design

ISO 13485-2016

ISO 9001

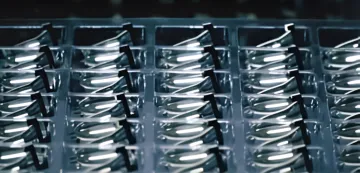

Professional diffractive optical element fabrication services specializing in custom precision optics for medical, defense, automotive, and commercial applications. Apollo Optical Systems creates lightweight, high-efficiency diffractive elements using advanced single-point diamond turning and polymer injection molding technologies.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

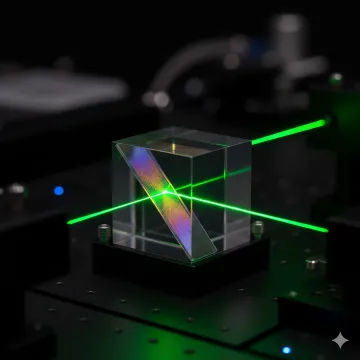

What diffraction efficiency can you achieve with your diffractive optical elements?

Our diffractive optical elements achieve 97% to 99% diffraction efficiency at design wavelengths with RMS surface finishes of 1.5 nanometers.

What materials can be used for diffractive optical element fabrication?

What manufacturing methods do you use for diffractive optics?

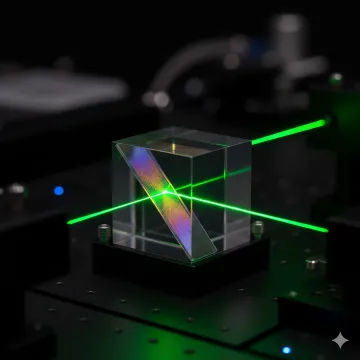

What applications are diffractive optical elements suitable for?

What quality certifications do you maintain for medical device applications?

What size range can you manufacture for diffractive optical elements?

Do you provide design services for custom diffractive optical elements?

Talk to our experts for custom solutions and tailored guidance.

Precision optics for endoscopes, intraocular lenses, diagnostic equipment, and medical sensing devices.

Critical optical components for scopes, night vision, guidance systems, and aerospace lighting applications.

Lightweight, high-performance optics for VR headsets, AR displays, and head-mounted display systems.

Advanced lighting solutions, LIDAR components, and sensor optics for modern automotive applications.

Talk to our experts for custom solutions and tailored guidance.

Complete in-house capabilities from design to production with advanced diamond turning and injection molding facilities in our 21,000 sq. ft. facility.

RMS surface finishes of 1.5 nanometers and 97-99% diffraction efficiency backed by comprehensive in-house metrology and quality assurance.

Since 2002, we've delivered mission-critical optical solutions for global leaders in medical devices, defense systems, and commercial applications.

Submit your requirements and receive technical consultation from our optical engineers within 24 hours.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com