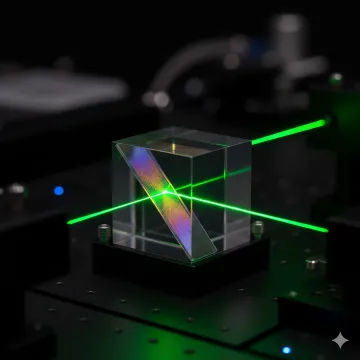

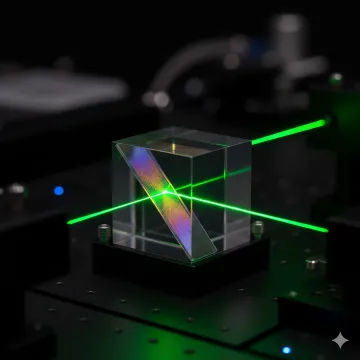

Diffractive Optical Elements

- 97-99% diffraction efficiency

- 1.5nm RMS surface finish

- Lightweight large apertures

ISO 13485-2016

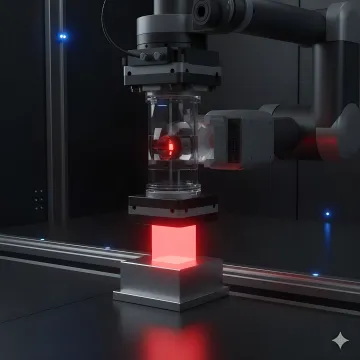

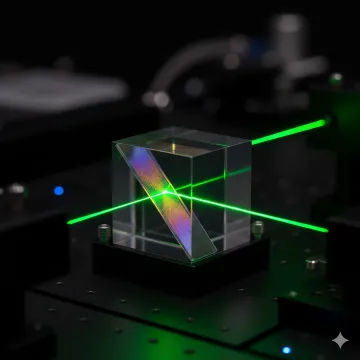

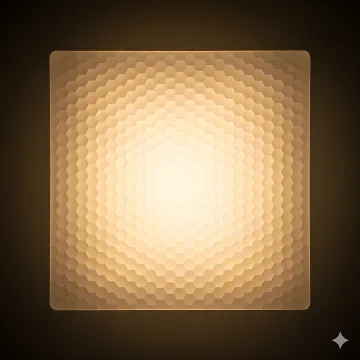

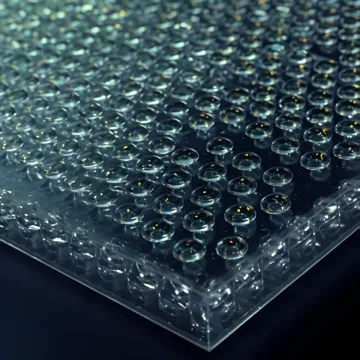

Diffractive Optical Elements (DOE) represent cutting-edge optical technology that manipulates light through microscopic surface structures. These precision-engineered components create lightweight, cost-effective solutions for applications ranging from medical devices to AR/VR displays, offering superior performance over traditional refractive systems.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

What are diffractive optical elements and how do they work?

DOEs use microscopic surface structures to manipulate light through diffraction, creating lightweight alternatives to traditional refractive optics with superior performance.

What diffraction efficiency can be achieved with Apollo's DOEs?

What materials are used for manufacturing DOEs?

What applications benefit most from diffractive optical elements?

How do DOEs compare to traditional refractive optics?

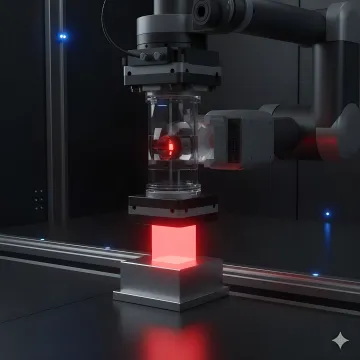

What manufacturing methods does Apollo use for DOEs?

Can diffractive optical elements be customized for specific applications?

Talk to our experts for custom solutions and tailored guidance.

DOEs enable precision optics for endoscopes, intraocular lenses, laser surgery systems, and diagnostic equipment

Lightweight polymer DOEs provide superior image quality and reduced system complexity for AR/VR headsets

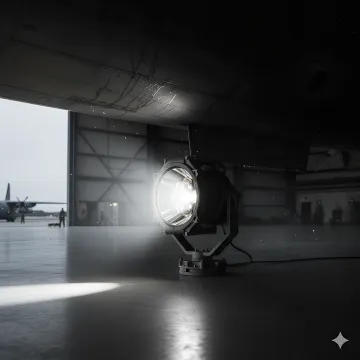

Critical weight reduction and performance requirements met with precision DOEs for guidance systems and displays

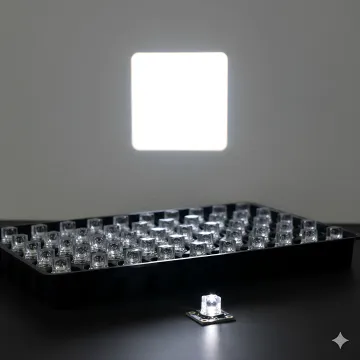

Advanced lighting systems and sensor applications utilize DOEs for improved efficiency and compact design

Talk to our experts for custom solutions and tailored guidance.

Single-point diamond turning and advanced metrology ensure RMS surface finishes of 1.5 nanometers with 97-99% diffraction efficiency for critical applications.

Complete capabilities from design and prototyping to high-volume production with 21,000 sq ft facility and comprehensive coating and testing services.

Over 20 years of expertise serving medical, aerospace, and defense sectors with ISO 13485-2016 certification and trusted supply chain reliability.

Connect with our optical engineers for technical consultation and custom DOE solutions tailored to your specific application requirements.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com