Aerospace Optical Components

- Lightweight aerospace designs

- < ¼ wave surface form in metals

- 1mm to 300mm diameter range

ISO 13485-2016

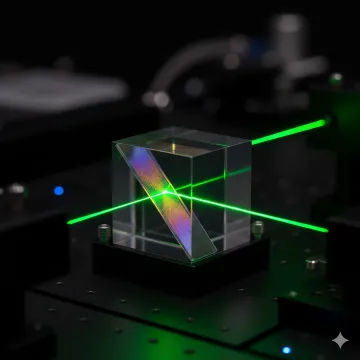

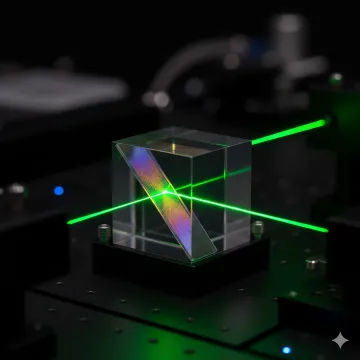

Infrared optical components are precision-engineered elements designed to manipulate, transmit, or modify infrared light in advanced optical systems. Our product line includes diffractive optical elements, beam splitters, and aerospace-grade components manufactured using single-point diamond turning and polymer injection molding. These components deliver exceptional surface finishes, lightweight designs, and superior wavefront control for demanding applications in defense, aerospace, medical devices, and industrial systems requiring infrared wavelength performance.

What are IR components?

IR components are precision optical elements designed to manipulate infrared wavelengths, including lenses, beam splitters, diffractive optics, and reflectors used in thermal imaging, night vision, and infrared sensing systems.

What materials are used for infrared optical components?

What manufacturing methods do you use for precision IR optics?

What surface finishes can you achieve on infrared optical components?

Can you create custom infrared optical designs?

What size range of infrared components can you manufacture?

What quality certifications do your infrared optical components meet?

Talk to our experts for custom solutions and tailored guidance.

Lightweight infrared optics for night vision devices, guidance systems, emergency lighting, and landing lights in aerospace applications.

High-precision diffractive optics and beam splitters for vision correction devices, laser surgery systems, and diagnostic imaging equipment.

Advanced beam splitters and infrared optics for automotive sensing, head-up displays, driver monitoring, and autonomous vehicle vision systems.

Lightweight diffractive optical elements and precision optics for augmented reality, virtual reality headsets, and advanced display projection systems.

Talk to our experts for custom solutions and tailored guidance.

From single-point diamond turning to polymer injection molding and precision coating, our 21,000 sq. ft. facility delivers complete optical solutions under one roof with ISO-certified quality.

Over 20 years of expertise in precision polymer optics, delivering nanometer-level surface finishes and wavefront control for the most demanding aerospace, defense, and medical applications.

Rapid prototyping capabilities combined with high-volume production expertise ensure your optical designs move from concept to deployment with speed, consistency, and cost-effectiveness.

Connect with our optical engineering team for technical consultation, custom design support, and rapid prototyping services for your precision infrared optical systems.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com