Diffractive Optical Elements

- 97-99% diffraction efficiency

- 1.5nm RMS surface finish

- Lightweight achromatic design

ISO 13485:2016

Explore precision infrared optics engineered for industrial imaging and detection systems. Apollo Optical Systems manufactures diffractive elements, aspheric lenses, beam shapers, and specialized optical components optimized for IR wavelengths. Our polymer and metal optics deliver superior thermal performance, lightweight construction, and cost-effective solutions for thermal imaging, night vision, spectroscopy, and process monitoring applications.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

What are infrared optics?

Infrared optics are specialized optical components designed to transmit, focus, or manipulate infrared wavelengths for thermal imaging, detection, and industrial sensing applications.

What is the meaning of infrared optics?

What materials are best for infrared optical components?

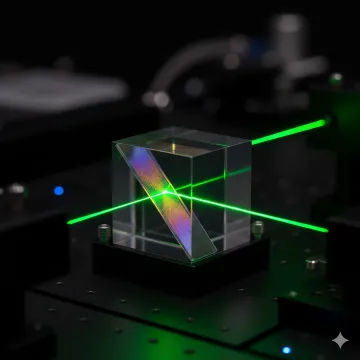

How are diffractive optics used in IR imaging systems?

What manufacturing methods are used for IR optics?

Can infrared optics be customized for specific applications?

What quality standards apply to infrared optical components?

Talk to our experts for custom solutions and tailored guidance.

Precision IR optics for endoscopes, diagnostic imaging, medical sensing devices, and surgical equipment requiring thermal detection.

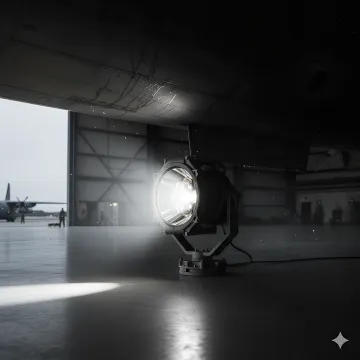

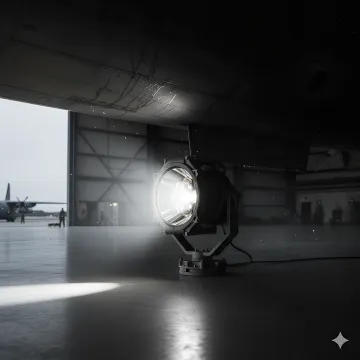

Lightweight IR optical components for night vision, targeting systems, thermal scopes, and aerospace detection equipment.

IR imaging optics for process monitoring, quality inspection, semiconductor equipment, and thermal detection systems.

Infrared optical components for ADAS, LIDAR systems, driver monitoring, and advanced automotive sensing applications.

Talk to our experts for custom solutions and tailored guidance.

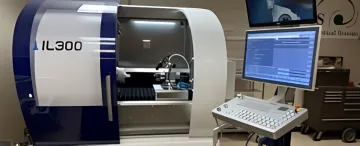

Advanced single-point diamond turning and injection molding capabilities deliver RMS surface finishes down to 1.5 nanometers with diffraction efficiencies up to 99% for critical IR applications.

From custom optical design and prototyping to high-volume manufacturing and coating, we manage your entire infrared optics program in our 21,000 sq. ft. Rochester facility.

ISO 13485:2016 certified manufacturing processes ensure consistent performance and regulatory compliance for medical devices, defense systems, and industrial applications requiring infrared imaging.

Our optical engineering team will respond within 24 hours to discuss your IR imaging requirements, specifications, and application needs.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com