Refractive Optical Elements

- Large aperture lightweight design

- Achromatic single-material lenses

- 1mm-300mm diameter range

ISO 13485-2016

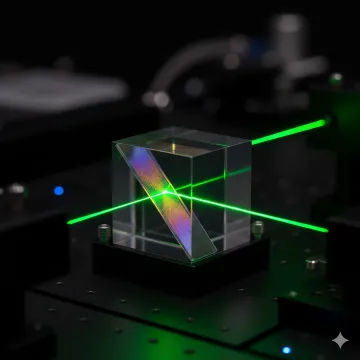

Apollo Optical Systems manufactures precision optical devices and components for industrial, medical, automotive, aerospace, and consumer applications. Our product line includes refractive elements, freeform lenses, diffractive optics, beam shapers, optical windows, and engineered illumination systems. Manufactured using advanced injection molding and single-point diamond turning, our components deliver superior performance with tight tolerances and exceptional surface finishes.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

What are the 10 optical instruments?

Common optical instruments include microscopes, telescopes, cameras, binoculars, spectrometers, periscopes, magnifying glasses, projectors, endoscopes, and optical sensors. Apollo manufactures precision components for many of these applications.

What is an example of an optical device?

What materials are used for precision optical components?

What manufacturing methods does Apollo use for optical components?

What surface finishes can Apollo achieve on optical components?

Are Apollo's optical components certified for medical device applications?

What size range of optical components can Apollo manufacture?

Talk to our experts for custom solutions and tailored guidance.

Precision polymer optics for endoscopes, diagnostic equipment, optical covers, pulse oximeters, and surgical tracking systems.

Optical components for ADAS sensors, LIDAR windows, interior/exterior lighting, and advanced driver assistance systems.

Lightweight optical elements for reading lights, emergency lighting, night vision devices, scopes, sights, and guidance systems.

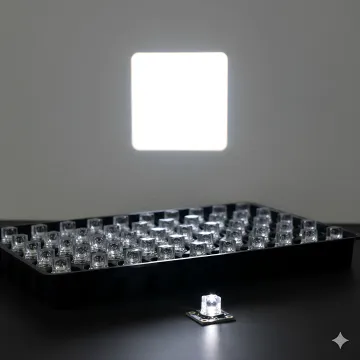

Freeform lenses and diffractive optics for AR/VR displays, smartphone cameras, head-mounted displays, and imaging systems.

Talk to our experts for custom solutions and tailored guidance.

ISO 13485-2016 certified with rigorous quality control throughout manufacturing, ensuring medical-grade precision for demanding optical applications across industries.

Complete in-house facilities including single-point diamond turning, polymer injection molding, precision machining, advanced coating, and comprehensive metrology for seamless production.

Since 2002, delivering precision polymer and metal optics with nanometer-level surface finishes and tight tolerances for medical, aerospace, automotive, and defense applications.

Connect with our optical engineering experts to discuss your project requirements. Receive technical guidance and custom solutions within 24-48 hours.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com