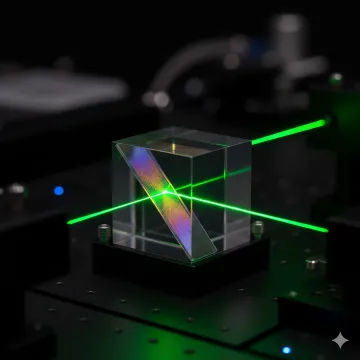

Refractive Optical Elements

- Large aperture lightweight design

- Single material achromatic lenses

- 1mm to 300mm diameter range

ISO 13485:2016

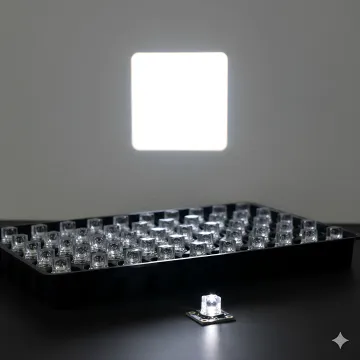

Apollo Optical Systems manufactures precision optical elements and components using advanced polymer and metal fabrication techniques. Our comprehensive product line includes refractive lenses, diffractive optics, Fresnel lenses, beam shapers, and custom optical solutions engineered for medical, aerospace, automotive, and industrial applications. With ISO 13485 certification and over 20 years of manufacturing excellence, we deliver lightweight, high-performance optical components from 1mm to 300mm in diameter.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 16 results

What materials can be used for precision optical elements?

We manufacture optical components in PMMA, polycarbonate, polystyrene, cyclic olefin polymers (COP/COC), ULTEM, and metals including nickel, brass, copper, and aluminum for various applications.

What size range of optical components can Apollo manufacture?

What manufacturing methods are available for optical elements?

What tolerances can be achieved for optical components?

Are Apollo's optical components certified for medical applications?

What coating options are available for optical elements?

Can Apollo design custom optical solutions?

Talk to our experts for custom solutions and tailored guidance.

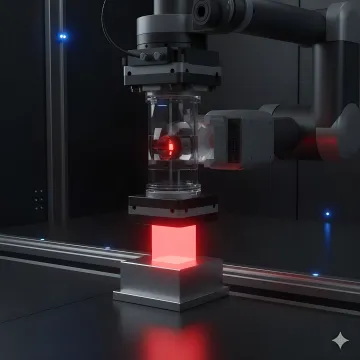

Precision polymer optics for endoscopes, diagnostic equipment, medical sensing, pulse oximeters, and optical covers meeting ISO 13485 standards.

Lightweight optical solutions for LIDAR windows, automotive lighting, ADAS sensors, head and tail lights, and interior illumination systems.

Engineered optical components for scopes, night vision, tactical sights, aircraft lighting, emergency lighting, and guidance systems.

High-performance optics for AR/VR headsets, smartphone cameras, head-mounted displays, and advanced imaging consumer devices.

Talk to our experts for custom solutions and tailored guidance.

ISO 13485-certified precision optical manufacturing with advanced metrology ensures consistent quality and performance for medical device and critical applications from prototype to high-volume production.

Complete in-house capabilities from optical design and diamond turning to polymer injection molding, coating, and assembly in our 21,000 sq. ft. Rochester facility accelerates your time-to-market.

Over 20 years specializing in lightweight polymer and metal optics from 1mm to 300mm diameter, with surface finishes down to 30 Å RMS and tolerances to ±0.002mm for demanding applications.

Connect with our optical engineering team to discuss your project requirements. We'll provide technical guidance and a detailed quote tailored to your specifications.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com