Microlens Arrays

Microlens arrays are finding uses in a wide variety of optical systems and applications, such as:

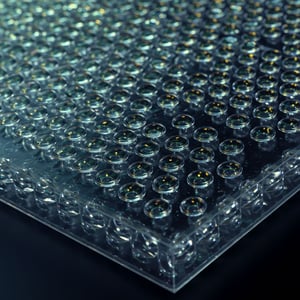

Courtesy of RPC Photonics

- Displays

- Illumination systems

- Solid-state lighting

- Semiconductor processing

- Medical systems

- Beam shaping

- Beam homogenizers

- Laser micro-machining

- Detector arrays

- Laser-diode arrays

- Spatial light modulators

- Wavefront sensors

- Optical interconnections

- Optical computing

- Image processing

- Imaging systems

- Confocal microscopy

Versatile Microlens Arrays: Apollo & RPC Photonics Partnership

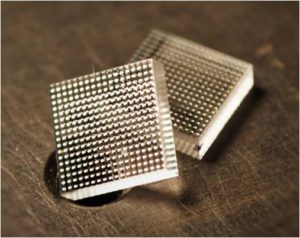

Apollo Optical Systems can provide injection-molded microlens arrays, produced from masters fabricated using RPC Photonics state-of-the-art laser writing process. This combination provides complete flexibility for both the array geometry (square, hexagonal, rectangular, circular, random) and the sag profile of the array elements (spherical, conic, general aspheric custom). Please visit the RPC Photonics website (http://www.rpcphotonics.com/product-category/microlens-arrays/) for more information on microlens array capabilities.

SCHEDULE A MEETING WITH AN EXPERT

FAQ – Microlens Arrays

1. How Does a Microlens Array Work?

Microlens arrays are optical components that consist of an array of small lenses, often arranged in a grid pattern. Each lens is small, typically about a millimeter or less, and manipulates light in various ways. They’re typically arranged in a square or hexagonal layout to focus or diverge light based on the curvature of the individual lenslets.

2. What Are the Applications of Microlens Arrays in Technology and Industry?

Microlens arrays have a range of applications across various fields of technology and industry. Their ability to manipulate light at a microscale makes them valuable for applications like:

- Displays and projection systems, such as LCDs, which improve light efficiency, brightness, and viewing angles

- Imaging and cameras to enhance image quality in low-light conditions

- Optical microscopy to enhance contrast and achieve better imaging performance

- LED technology to enhance light extraction efficiency by directing light in the desired direction

- Laser applications to create specific beam profiles for laser cutting, laser material processing, and laser marking

- Optical switches, modulators, and fiber optic components to manipulate light signals in optical communication systems

- Microfluidic channels to analyze small volumes of liquids

- Solar concentrators to focus sunlight into solar cells

- Holography and diffraction applications for unique optical effects

- Augmented and virtual reality to improve image quality and visual experience

3. How Are Microlens Arrays Manufactured, and What Materials Are Typically Used?

Microlens arrays are manufactured using specialized microfabrication techniques to create miniature lenses with micrometer-scale precision. Several techniques may be used, including:

- Photolithography, which uses a patterned mask to expose photosensitive material on a substrate. The exposed areas are then developed to create the desired lens shapes.

- Reflow process, which applies a thin layer of photoresist to the substrate. Heat is then applied to soften it, causing it to flow and form lens shapes.

- Laser ablation, which focuses laser pulses onto the substrate and removes material to form the lens structures.

- Laser writing, which focuses laser beams to create high-resolution lens shapes

- Single point diamond turning, which uses a small diamond tool with a precision lathe-like diamond turning machine to produce either an array directly or a master that can be used for mass production via injection molding.

The materials used in microlens arrays may include polymers, glass, chalcogenide glass, and hybrid materials with polymer, glass, or silicon.

4. Can Microlens Arrays Be Customized to Specific Applications and Requirements?

One of the most significant advantages of microlens arrays is that they are customizable to specific applications and requirements. During the design phase, they can be adjusted to achieve specific optical effects, adapt to wavelength ranges, and meet the unique needs of different industries and applications.

There are many ways to customize microlens arrays, including the array layout, the focal length, beam profile, and wavelength range. The design can also support focusing, collimating, diverging, or shaping light beams. Microlens arrays also support different materials and can withstand specific environmental conditions, such as temperature and humidity variations.

5. What Are the Advantages of Using Microlens Arrays in Optical Systems?

Using microlens arrays in optical systems offers multiple advantages:

- Miniaturization for compact optical systems where space is limited or portability is important

- Efficient light collection and refocusing into wider areas for better sensitivity

- Improved brightness and efficiency in light-emitting elements like LEDs

- Precision beam manipulation with lasers

- Improved depth perception with 3D light and imaging systems

- The ability to correct for aberrations and improve image quality in real time

- Reduced glare and ghosting that impact image clarity and quality

- Tailored optical effects, such as beam splitting, light homogenization, and diffraction patterns

6. How Do Microlens Arrays Compare to Other Types of Optical Components Such as Lenses or Prisms?

Microlens arrays, lenses, and prisms all serve different purposes and enhance different effects. Microlens arrays are used for light collection, beam shaping, beam steering, and improving imaging performance. They’re ideal for compact optical systems and highly customizable, but they are complex and have limited focusing power.

Lenses are used to refract or focus light to form an image or change the direction of light beams. They can be convex, concave, or other shapes. Lenses are ideal for tight focus, varying focal lengths, and simple designs, but they’re not ideal for miniaturization or shaping light.

Prisms are transparent optical elements that can refract or reflect light. They’re used for light redirection, dispersion, and beam splitting. Prisms are ideal for dispersing and reflecting light in applications like spectroscopy, but they have limited focus and can be larger and heavier than other optical components.

7. How Do Microlens Arrays Impact the Overall Performance and Resolution of Imaging Systems?

Microlens arrays can significantly impact the overall performance and resolution of imaging systems. They improve light collection by efficiently collecting and focusing light into imaging sensors and increasing the light that reaches each pixel. They also make imaging systems more sensitive and reduce pixel crosstalk, which enhances image sharpness.

In depth-sensing cameras, microarrays capture depth information efficiently by analyzing the disparities in images captured by different lenses. They’re also used in 3D imaging to capture different perspectives and enable the creation of 3D images.

8. What Are the Key Considerations to Keep in Mind When Designing or Integrating Microlens Arrays into a Larger Optical System?

The design and integration of microlens arrays are key considerations in the final product’s performance and functionality. It’s essential to understand the application’s specific requirements, including the desired optical effects and resolution and the appropriate parameters like lens curvature, focal length, and array layout. Choosing the appropriate materials is also vital to maximize performance in the finished optical system.