In modern manufacturing, the accuracy of visual inspection directly impacts product quality, operational costs, and customer satisfaction. Traditional inspection methods often struggle to detect micro-defects, maintain consistent throughput, and deliver repeatable results. This can lead to increased scrap rates, unplanned downtime, and inefficiencies in production lines.

Optical lenses have emerged as a critical component in quality control systems, enabling precise imaging, consistent defect detection, and faster inspection cycles. This shift is reflected in the rapid growth of the global optical lens market, which is projected to reach USD 44.28 billion by 2034, as demand for high-precision inspection continues to rise.

By integrating advanced optical lenses, manufacturers can improve yield, reduce costs per unit, and maintain tighter process control. This blog explores the role of optical lenses for quality control, key properties and technologies, and selection factors.

Key Takeaways:

Optical lenses are essential for precise visual inspection, improving defect detection, throughput, and overall production quality.

Lens properties such as focal length, numerical aperture, resolution, material, and coatings directly influence image clarity, accuracy, and reliability.

Different lens types; standard, telecentric, aspheric, Fresnel, diffractive, microlens arrays, and custom polymer optics, serve specific inspection needs and applications.

Lenses function by controlling light interaction, focusing details, forming usable images, supporting automated analysis, and maintaining consistent performance over time.

Selection factors include lighting, inspection requirements, throughput, environmental conditions, system integration, and supplier capabilities to ensure reliable, repeatable quality control.

What Are Optical Lenses and Why They Matter for Enhanced Quality Control?

Optical lenses are transparent components that bend and focus light to create clear images of the objects you’re inspecting. In quality control environments, their role goes beyond magnification and directly affects inspection reliability and production outcomes.

Here’s why it matters:

Define inspection accuracy: Optical lenses determine image clarity, contrast, and distortion levels, which directly affect your ability to detect surface defects, dimensional deviations, and inconsistencies.

Reduce false rejects and misses: Well-designed lenses help inspection systems distinguish real defects from noise, lowering scrap rates and reducing rechecks.

Support consistent throughput: Clear, repeatable imaging keeps inspection cycles smooth, avoiding slowdowns from repeated scans or manual verification.

Enable tighter process control: High-quality lenses provide consistent visual data across shifts and batches, supporting yield stability and predictable quality outcomes.

Influence long-term system reliability: Durable optical lenses maintain performance over time, reducing maintenance-related downtime and inspection drift.

Also Read: Top 3 Considerations When Moving from Glass to Polymer for Your Optic Project

Key Properties of Optical Lenses

Understanding the critical properties of optical lenses helps decision-makers match lens performance with inspection objectives. Each property influences the clarity, precision, and reliability of the images captured.

Key properties include:

Focal Length: Determines how closely an image can be focused. Short focal lengths are suitable for detailed inspection of small parts, while longer focal lengths provide a broader field of view for larger components.

Numerical Aperture (NA): Higher NA lenses capture more light, capturing clearer images and defect detection. In industrial inspection, this translates to a better ability to identify micro-defects without slowing production lines.

Resolution: A lens's ability to distinguish fine details impacts defect identification. Higher resolution lenses support tighter tolerances and reduce scrap rates.

Material: Lens material affects durability, optical clarity, and environmental resistance. Polymer optics, like acrylic or Zeonex, can be lightweight and impact-resistant, while glass may provide higher stability for critical inspections.

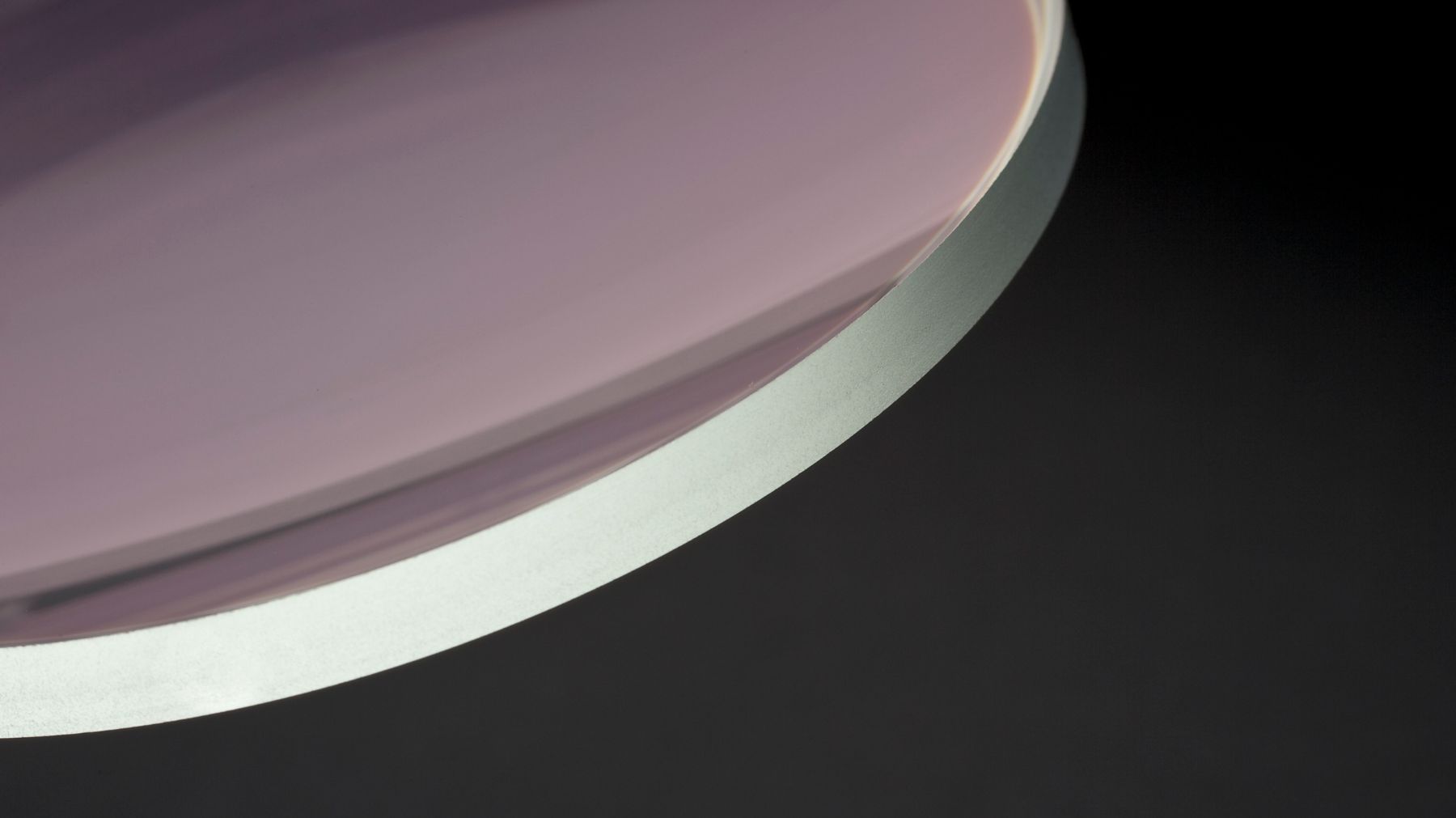

Coatings: Anti-reflective (AR) or metallic coatings improve light transmission, reduce glare, and increase inspection accuracy.

Tolerance and Surface Quality: The precision of the lens shape directly affects image quality. Lenses with low surface error and high uniformity are preferred for high-precision inspection.

All of these properties impact measurable inspection outcomes: defect detection accuracy, cycle time stability, scrap reduction, and overall inspection confidence.

Types of Optical Lenses Used in Quality Control Applications

Different inspection needs call for different lens designs. Understanding the types and when to apply them is essential for choosing the right lens for your inspection system.

Standard (Fixed Focal Length) Lenses

Standard lenses use a fixed focal length and are designed for inspection setups where the distance between the camera and the part remains stable. They provide reliable image quality when parts are uniform and positioned consistently on the inspection line.

These lenses are widely used because they are simple to integrate and maintain. However, they are sensitive to distance variation, which can impact measurement accuracy if part positioning changes.

Ideal use case scenario: Fixed inspection stations checking surface defects or presence/absence on consistent, repeatable parts.

Telecentric Lenses

Telecentric lenses are designed to eliminate perspective distortion by keeping magnification constant, even when parts shift slightly along the optical axis. This is critical for dimensional inspection, where measurement accuracy directly affects acceptance or rejection decisions.

By reducing measurement variability, telecentric lenses help stabilize inspection results and reduce false rejects that can increase scrap and rework.

Ideal use case scenario: High-precision dimensional inspection where consistent measurements are required despite minor part position variation.

Aspheric Lenses

Aspheric lenses use non-spherical surfaces to reduce optical aberrations that can blur edges or reduce contrast. This makes edges sharper across the entire field of view, not just the center.

In quality control, sharper edge definition supports more reliable detection of fine surface defects and improves image clarity for automated vision algorithms.

Ideal use case scenario: Inspection of fine features, sharp edges, or micro-defects where image clarity directly affects defect classification.

Fresnel Lenses

Fresnel lenses achieve light focusing using a stepped surface structure, allowing them to remain thin and lightweight while maintaining optical performance. Designers often use them when space or weight constraints limit traditional lens designs.

While not ideal for high-precision metrology, they are effective in applications that require broad area inspection or light redirection.

Ideal use case scenario: Large-area inspection or compact inspection systems where weight and space constraints matter more than extreme precision.

Diffractive Optical Elements (DOEs)

Diffractive optics uses micro-structured patterns to control light behavior, often combining multiple optical functions into a single element. This enables compact optical systems with controlled light distribution.

In quality control, DOEs are often used to improve illumination uniformity or increase contrast for specific inspection tasks.

Ideal use case scenario: Specialized inspection setups requiring controlled illumination or compact optical paths.

Microlens Arrays

Microlens arrays consist of many small lenses arranged in a grid. They are used to shape or redistribute light, improve illumination uniformity, or enable structured-light inspection techniques.

These lenses support advanced inspection methods such as 3D surface profiling, where depth and shape information are required to validate part quality.

Ideal use case scenario: 3D inspection, surface profiling, or structured-light systems are used for shape and flatness verification.

Custom Polymer Optical Lenses

Custom polymer lenses are designed and molded to meet specific inspection requirements, including size, weight, material compatibility, and environmental durability. Polymer optics allow scalable production for high-volume inspection systems.

These lenses allow manufacturers to balance optical performance with cost control and system durability.

Ideal use case scenario: High-volume inspection systems require custom optics that support consistency, durability, and long-term cost control.

Also Read: The Role of Optics in Metrology

Each lens type affects inspection consistency, throughput, and yield outcomes differently. The right choice depends on part geometry, surface type, inspection distance, and lighting conditions.

How Do Optical Lenses Work?

Optical lenses are fundamental to image-based inspection systems. They shape light so that cameras and sensors can reliably capture accurate visual information about a part’s surface, dimensions, and features.

Below is a step-by-step breakdown of how optical lenses function within quality inspection systems.

Step 1: Controlling How Light Interacts with the Part

Optical lenses first manage how light reaches and reflects off the component being inspected. This step is critical because uneven or uncontrolled light can hide surface defects or create false signals.

Well-designed lenses:

Direct light evenly across the inspection area

Reduce glare and shadowing on reflective or transparent surfaces.

Sharpen contrast between acceptable features and defects

This directly supports more consistent defect visibility, helping reduce inspection variability that can increase scrap or rework.

Step 2: Focusing Light to Capture Fine Details

Once light interacts with the part, the lens focuses it onto a sensor or viewing plane. The quality of this focus determines whether small defects are clearly visible or lost in blur.

High-precision optical lenses:

Maintain sharp focus across the full field of view

Reduce optical distortions that affect measurement accuracy.

Support tighter inspection tolerances without slowing inspection speed

Accurate focus improves first-pass inspection reliability, maintains stable throughput, and lowers false rejects.

Step 3: Converting Optical Information into Usable Image Data

After focusing the light, the lens forms an image that inspection cameras or sensors can capture. This image becomes the input for human inspectors or automated vision systems.

At this stage, how the lens performs directly impacts:

Image clarity and resolution

Edge definition for dimensional checks

Repeatability across multiple inspection cycles

Clear, repeatable image formation helps maintain consistent quality decisions, reducing operator dependency and inspection drift over time.

Step 4: Supporting Automated Analysis and Decision-Making

In automated quality control systems, images produced by optical lenses are processed by software to identify defects, misalignments, or surface irregularities.

Properly selected optical lenses:

Improve defect detection reliability in machine vision systems

Reduce false positives that slow production.

Maintain stable inspection cycle times

This step is essential for maintaining equipment uptime and preventing inspection-related bottlenecks on production lines.

Step 5: Maintaining Performance Over Production Scale and Time

Optical lenses must continue performing consistently as production volumes increase and operating conditions vary. Material selection, surface quality, and coatings influence long-term inspection reliability.

High-quality lenses help:

Maintain consistent inspection results across shifts and batches

Reduce recalibration frequency

Support long-term inspection stability

This consistency is critical for controlling supplier risk, maintaining lead time predictability, and avoiding quality escapes.

Factors to Consider When Selecting Optical Lenses for Quality Control

Choosing the right lens for your quality control application involves multiple factors that directly impact operational performance.

Key factors include:

Lighting Conditions: Lenses interact with illumination. Coating quality and transmission affect how well the system manages glare or low‑contrast defects.

Inspection Requirements: Define target defect size, surface characteristics, and measurement precision. This informs lens type, focal length, and numerical aperture.

Throughput Needs: Choose a lens configuration that matches production speed without sacrificing image quality. High throughput reduces lead time variability and improves process stability.

Environmental Conditions: Temperature, vibration, and exposure to chemicals influence lens material selection. Durable materials support reliable, long-term operation.

Integration with Imaging Systems: Align lenses with cameras and sensors for optimal field-of-view and resolution. Misalignment can cause false defects, increased scrap, and rework.

Supplier Capabilities: Working with experienced manufacturers ensures lenses meet tight tolerances, are repeatable across batches, and support rapid prototyping to high-volume production.

Each of these factors directly influences measurable metrics like defect catch rates, inspection repeatability, and cycle time stability.

How Apollo Optical Systems Supports Advanced QC with Optical Lenses?

Apollo Optical Systems specializes in designing and manufacturing custom optical components that support high-precision quality control across industries. Their expertise spans polymer optics, diffractive lenses, microlens arrays, and coatings, enabling manufacturers to deploy reliable inspection systems.

Here’s how we can assist you:

Custom Lens Design: Apollo’s design services tailor lens properties to the specific inspection requirements, improving defect detection and yield.

Rapid Prototyping: SPDT and in-house modeling allow quick development of inspection lenses, reducing lead time and accelerating system deployment.

Scalable Production: High-volume polymer injection molding ensures consistent lens quality across thousands or millions of units, supporting throughput and cost stability.

Advanced Coatings: AR and metallic coatings improve light transmission and reduce glare, critical for accurate inspections in reflective environments.

Assembly and Testing: Apollo integrates lenses into inspection sub-assemblies and performs rigorous metrology, ensuring operational reliability and repeatability.

ISO-Certified Quality Assurance: Supports regulated industries such as medical devices, aerospace, and automotive, ensuring inspection repeatability and compliance.

With these capabilities, Apollo Optical Systems helps manufacturers implement inspection solutions that reduce scrap, improve yield, and maintain consistent operational KPIs.

Conclusion

Optical lenses play a critical role in modern quality control, directly influencing inspection accuracy, throughput, and overall production efficiency. By focusing on the right properties, technologies, and types of lenses, manufacturers can improve defect detection, reduce scrap, and stabilize yields across their production lines.

Investing in advanced optical lenses and partnering with experienced providers ensures that inspection systems remain reliable and future-ready. Experts like Apollo Optical Systems ensure access to precision lenses, advanced coatings, and integrated support from design through high-volume production.

Connect with us today to explore how Apollo Optical Systems can support your quality control systems with precision optical lenses.

FAQs

1. How do telecentric lenses improve accuracy in quality control?

Telecentric lenses maintain a constant magnification regardless of object distance, eliminating perspective errors. This ensures precise dimensional measurements and consistent imaging, making them ideal for high-accuracy quality control in manufacturing and inspection processes.

2. What role do machine vision lenses play in defect detection?

Machine vision lenses capture sharp, high-resolution images for automated inspection systems. By providing clear, distortion-free visuals, they enable software to accurately identify defects, inconsistencies, or irregularities on products, improving quality control efficiency and reducing errors.

3. Can aspheric lenses enhance optical quality control processes?

Aspheric lenses reduce optical aberrations and improve image clarity compared with standard spherical lenses. This allows precise detection of minute defects, sharper imaging, and better consistency in quality control applications, especially where fine details are critical.

4. How do optical lenses support non-contact inspection methods?

Optical lenses focus and magnify objects without physical contact, enabling accurate measurement and surface analysis. Non-contact inspection, such as laser or camera-based systems, relies on lenses to deliver precise imaging while avoiding potential damage or contamination of the product.

5. What applications use specialized lenses for surface flaw detection?

Specialized lenses are used in electronics, automotive, aerospace, and medical device manufacturing to detect scratches, cracks, or surface irregularities. They enhance imaging systems for precise flaw detection, ensuring product reliability, safety, and compliance with stringent quality standards.