In many optical systems, uneven light distribution is not a design flaw. It is an operational risk. Hot spots, falloff, and uncontrolled beam profiles can narrow process windows, increase rework, and make systems harder to tune at scale.

Beam-shaping optical films are often introduced when teams need predictable, repeatable light distribution without adding complexity to the optical stack. Used correctly, they support more stable illumination, cleaner processing outcomes, and easier system integration.

This article focuses on practical beam shaping techniques using optical films and how different approaches compare. And what engineering and operations teams should evaluate before committing to a solution that must perform reliably beyond the prototype stage.

Key Takeaways

Beam shaping is a control decision, not a theory exercise. Optical films are added when teams need stable, repeatable light behaviour that holds up in real systems, not just in simulations.

Uniformity and shape must match the application, not the beam. The right beam profile aligns light with how sensors, targets, or processes actually operate, reducing adjustment and rework.

Film type selection is only half the decision. Integration sensitivity, handling, and scalability often matter more than the shaping method itself once production begins.

Manufacturability determines long-term success. Beam shaping solutions that scale cleanly, inspect reliably, and integrate consistently reduce operational risk over the product lifecycle.

When Beam Shaping Optical Films Matter in Real Systems

Beam shaping optical films are usually added after teams encounter system-level limitations, not during early concept work.

Common triggers include:

Illumination that varies across the field, making calibration difficult

Hot spots that force conservative operating settings

Output patterns that do not align with sensors, targets, or processing areas

Tight process windows that drift over time or between builds

In these cases, beam shaping films help redistribute light in a controlled way, without redesigning the entire optical system.

They are commonly introduced in:

Illumination and sensing systems where uniformity affects signal consistency

Display and projection setups that require controlled light spread

Laser-based inspection or processing where energy placement influences repeatability

The value is not theoretical. It is about stabilising outcomes, reducing adjustment time, and supporting consistent performance as systems move from development into production.

What Engineers Mean by “Beam Shaping Optical Film”

In practice, the term beam shaping optical film does not describe a single technology. It is a functional label used for thin optical elements that redistribute light intensity or shape without adding bulky optics.

In production systems, teams usually mean one of the following:

Beam shaping diffusers: Used to smooth intensity variations or spread light in a controlled manner.

Flat-top or homogenising films: Used when uniform output across a defined area matters more than peak intensity.

Diffractive or holographic film-based elements: Used to generate specific intensity patterns or shapes within compact assemblies.

Micro-structured optical films: Used to redirect or redistribute light using surface features rather than bulk geometry.

These approaches are often chosen because films:

Fit into tight mechanical envelopes

Simplify alignment compared to multi-element optics

Scale more easily once a design is locked

The key decision is not the label. It is how the film reshapes light under real system constraints.

Flat-Top and Uniform Beam Shaping Films

Flat-top beam shaping films are used when output consistency matters more than peak brightness.

Instead of concentrating energy at the centre, these films redistribute light to create a more even intensity profile across the working area.

Teams typically consider flat-top approaches when they need to:

Reduce sensitivity to small alignment changes

Improve consistency across sensors, targets, or illuminated fields

Avoid over-processing at the centre while under-processing at the edges

Maintain stable results across multiple units or production runs

From an integration standpoint, engineers often evaluate:

How dependent the film is on the input beam condition

How tolerant the system is to small positional shifts

Whether the uniformity benefit justifies the added optical elements

Flat-top beam shaping films are not a universal solution. They are most effective when the system goal is repeatable, controlled output, rather than maximum intensity or highly structured patterns.

Shaping the Output Footprint: Circular, Square, Rectangular, and Line Patterns

In many systems, the shape of the illuminated area matters as much as uniformity.

A mismatch between the beam footprint and the target area can lead to wasted energy, inconsistent results, or unnecessary process tuning. Beam shaping optical films are often used to better align light distribution with how a system actually operates.

Teams typically evaluate footprint shaping when:

Sensors or detectors have rectangular or non-circular active areas

Processing or inspection targets follow a defined geometry

Coverage must be controlled to avoid spillover into non-critical regions

System efficiency depends on placing light only where it is needed

Common footprint choices include:

Circular patterns for rotational symmetry and general illumination

Square or rectangular patterns to match sensors, displays, or inspection fields

Line or elongated patterns where coverage along one axis matters more than the other

By shaping the footprint to the application, teams can simplify alignment, reduce edge effects, and achieve more predictable system behaviour across builds.

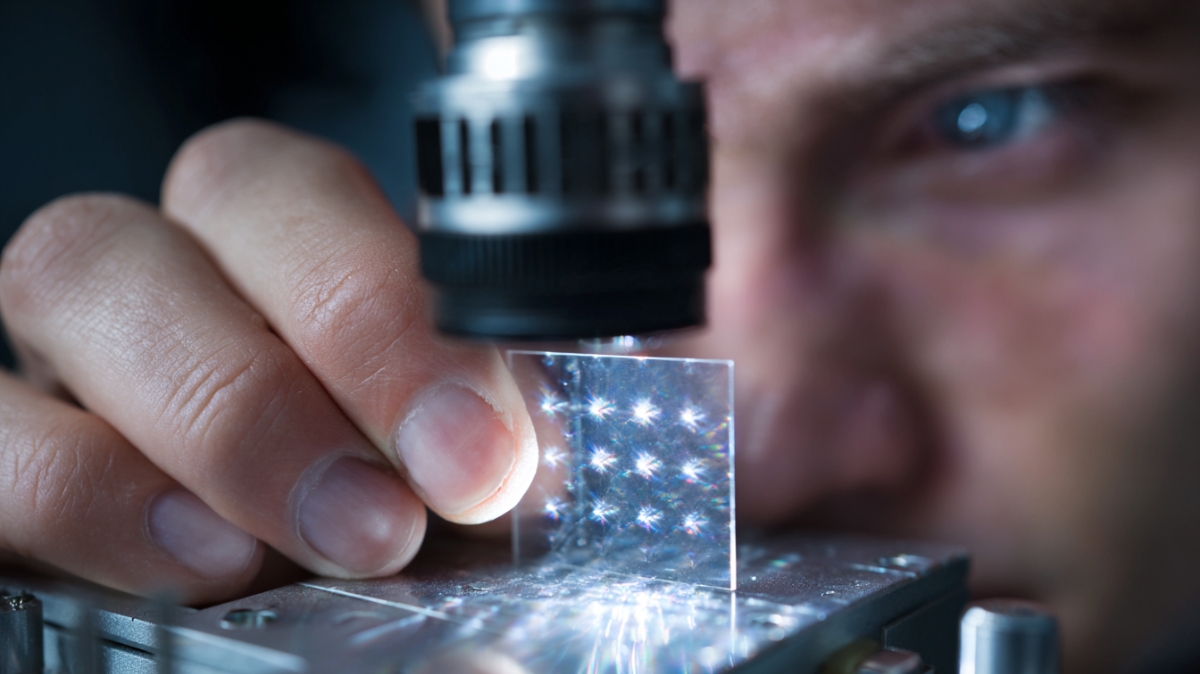

Diffractive and Holographic Optical Films for Pattern Control

Diffractive and holographic optical films are used when simple redistribution is not enough.

These approaches shape light by controlling phase rather than relying solely on diffusion or surface curvature. This allows more complex or highly defined output patterns within a thin optical form factor.

Teams often consider diffractive or holographic films when they need:

Structured intensity patterns

Precise placement of light across a field

Compact integration where space limits traditional optics

At the same time, these films introduce practical considerations that must be planned early:

Sensitivity to alignment and working distance

Dependence on stable input conditions

The need for careful validation in the final system environment

When applied with the right constraints in mind, diffractive and holographic films offer a powerful way to sculpt light while keeping optical assemblies compact and manufacturable.

Micro-Structured Films and Homogenizing Surfaces

Micro-structured optical films use controlled surface features to redistribute light rather than relying on bulk lens geometry. In practice, they are often used as homogenizers, helping smooth intensity variations across the output area.

Teams typically look at micro-structured films when they need to:

Reduce visible hot spots or banding

Improve perceived or measured uniformity across a field

Maintain a thin optical stack without adding complex assemblies

These films are commonly integrated into illumination, sensing, and display-related systems where space is limited and repeatability matters.

From an engineering and operations perspective, teams also plan for:

Potential pattern artifacts introduced by surface structures

Sensitivity to orientation during assembly

Handling and contamination risks during manufacturing and integration

When applied with proper validation, micro-structured films can support more stable output while keeping mechanical complexity low.

The key is understanding how the surface structure interacts with the full optical and mechanical stack, not evaluating the film in isolation.

How to Select a Beam Shaping Optical Film: An Engineering Decision Flow

Selecting a beam shaping optical film is less about finding the most advanced option and more about matching the approach to system constraints and production realities.

Many teams follow a practical decision flow:

Define the required output: Focus on the shape, coverage area, and level of uniformity needed at the working plane.

Understand system constraints: Consider available space, mounting tolerances, environmental exposure, and handling requirements.

Choose an approach class: Decide whether a diffuser-based, diffractive-based, or hybrid solution best fits the application.

Plan verification early: Establish how output stability and consistency will be evaluated in the actual system, not just on an optical bench.

This approach helps teams avoid late-stage redesigns and supports smoother transitions from development into production, where small variations can have outsized operational impact.

Manufacturing and Supplier Considerations That Affect Long-Term Performance

Beam shaping optical films are often validated during development, but challenges tend to appear when systems move toward volume production.

At this stage, manufacturing choices and supplier capability start to matter as much as optical design.

Teams usually look beyond the film itself and assess whether a supplier can:

Support design and manufacturability discussions early

Provide a clear path from prototype builds to repeatable production

Maintain consistency across runs as volumes increase

Inspect and verify output in a way that aligns with system requirements

From an operations perspective, these factors influence:

Yield stability across builds

Time spent adjusting or reworking assemblies

Confidence in lead times and supply continuity

Evaluating beam shaping films through a manufacturing lens helps reduce late-stage surprises and supports smoother scale-up, especially when optical performance must remain consistent across many units.

Common Failure Modes and How Teams Reduce Risk

Even well-designed beam shaping films can underperform if system-level risks are not addressed early.

Common issues teams encounter include:

Alignment sensitivity: Small positional changes can alter output patterns more than expected.

Unintended artifacts: Patterns such as banding or non-uniform regions may appear after integration.

Handling and contamination concerns: Films can be sensitive during assembly, cleaning, or maintenance.

Variation between builds: Differences between components or assemblies can affect repeatability.

Teams reduce these risks by validating films within the full system context, not just as standalone components. This includes considering mounting methods, environmental exposure, and inspection approaches before designs are locked.

Addressing these factors early supports more predictable performance and reduces the likelihood of downstream adjustments that affect schedules or output consistency.

Quick-Start Checklist: What to Prepare Before Engaging a Beam Shaping Film Partner

Preparing the right information upfront helps engineering and procurement teams move faster and avoid unnecessary iterations.

Before engaging a beam shaping optical film supplier, teams typically gather:

A high-level description of the light source and system geometry

The desired output pattern and where it must be formed

Available space and mounting constraints

Expected production volumes, even if only as ranges

Environmental, handling, or cleaning considerations

How success will be judged in production, such as consistency across units or reduced adjustment time

This information supports clearer discussions, faster feasibility assessments, and more confident decisions when selecting a beam shaping approach that must perform reliably beyond the prototype stage.

Where Apollo Optical Systems Fits in the Beam Shaping Workflow

Beam shaping optical films are rarely standalone decisions. Their performance depends on how well optical design, manufacturability, and system integration are aligned.

This is where Apollo Optical Systems typically supports engineering and operations teams.

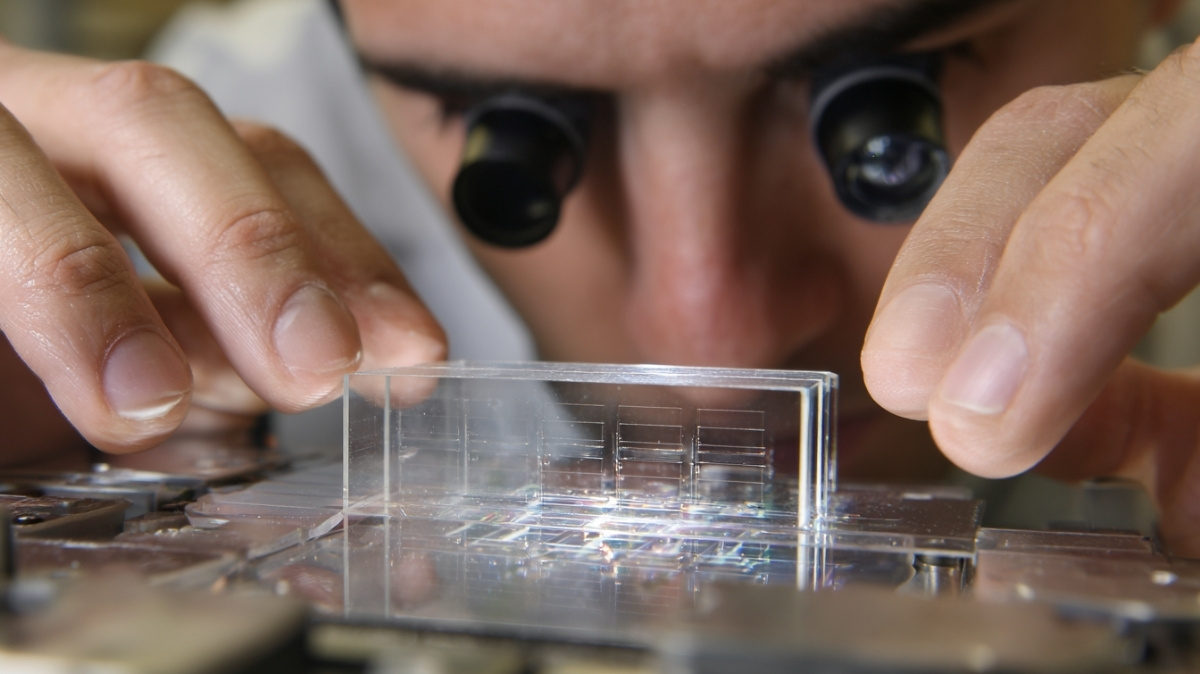

Optical design and engineering support: Collaborative development of beam shaping approaches aligned to system geometry, integration constraints, and production goals.

Design-for-manufacturing review: Early evaluation of film-based solutions to reduce variation, support repeatable builds, and avoid scale-related redesigns.

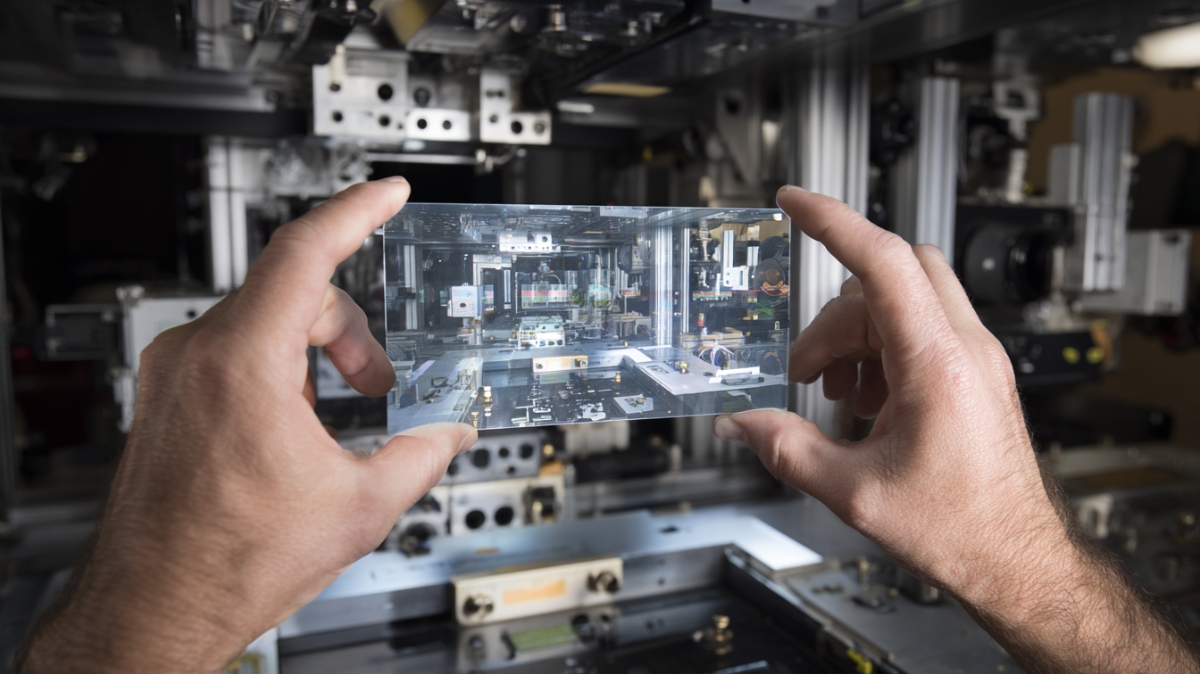

Rapid prototyping using SPDT: Validation of beam shaping concepts before committing to production tooling or volume processes.

Polymer-based optical manufacturing: Scalable production paths for beam shaping films and related optical components, supporting consistency across builds.

Custom optical coating services: Application of coatings to support durability, handling, and system-level performance requirements.

Optical assembly and integration support: Assistance with alignment-sensitive assemblies to help maintain consistent output in final systems.

Metrology and inspection: Verification of beam shaping performance using in-house optical testing and quality processes.

By consolidating these steps, teams can reduce handoffs between vendors, shorten iteration cycles, and limit integration risk as systems move from development into production.

Talk to an Apollo Expert to discuss how beam shaping optical films can be evaluated within your system and production requirements.

FAQs

1. Is a beam shaping optical film the same as a diffuser?

Not always. Diffusers spread light, while beam shaping films are designed to redistribute light into controlled patterns or uniform profiles.

2. Do beam shaping optical films only work for lasers?

No. They are used with lasers, LEDs, and other light sources, depending on system design and illumination goals.

3. Will a beam shaping film fix all uniformity issues in my system?

Not by itself. Performance depends on input conditions, alignment, and how the film interacts with the full optical and mechanical stack.

4. Are beam shaping optical films only suitable for prototypes?

No. Many are designed to support scalable manufacturing when manufacturability and inspection are considered early.

5. Does higher complexity always mean better beam shaping?

No. Simpler film-based solutions often provide more stable, repeatable results in production systems.