“Phase Fresnel vs diffractive optics” is usually a naming problem before it’s a design problem.

In most engineering contexts, a phase Fresnel lens is a type of diffractive optic; it sits inside the broader DOE family, not alongside it. Where teams get burned is when “Fresnel” is used loosely, mixing refractive stepped lenses, Fresnel zone plates, and phase structures in the same conversation or spec.

This guide does two things quickly: it pins down the terms so you’re comparing the right technologies, then it shows the practical tradeoffs that decide architecture bandwidth behavior, stray light risk, and what you must be able to manufacture and verify before you scale.

Key Takeaways

“Phase Fresnel” is typically a subset of diffractive optics, not a separate category.

Architecture is usually decided by bandwidth behavior, stray light risk, and verification feasibility, not just “thin vs thick.”

The right choice includes manufacturing and metrology gates from day one.

Hybrid refractive–diffractive designs are often the practical answer when you need compact packaging and controlled aberrations.

Phase Fresnel vs DOE

Most confusion in “phase Fresnel vs diffractive optics” comes from people comparing a specific optic type to a category of optics. If you don’t lock the language early, teams end up validating the wrong performance metrics and writing specs that suppliers interpret in different ways.

Here are the terms as they’re typically used in real engineering specs and design reviews:

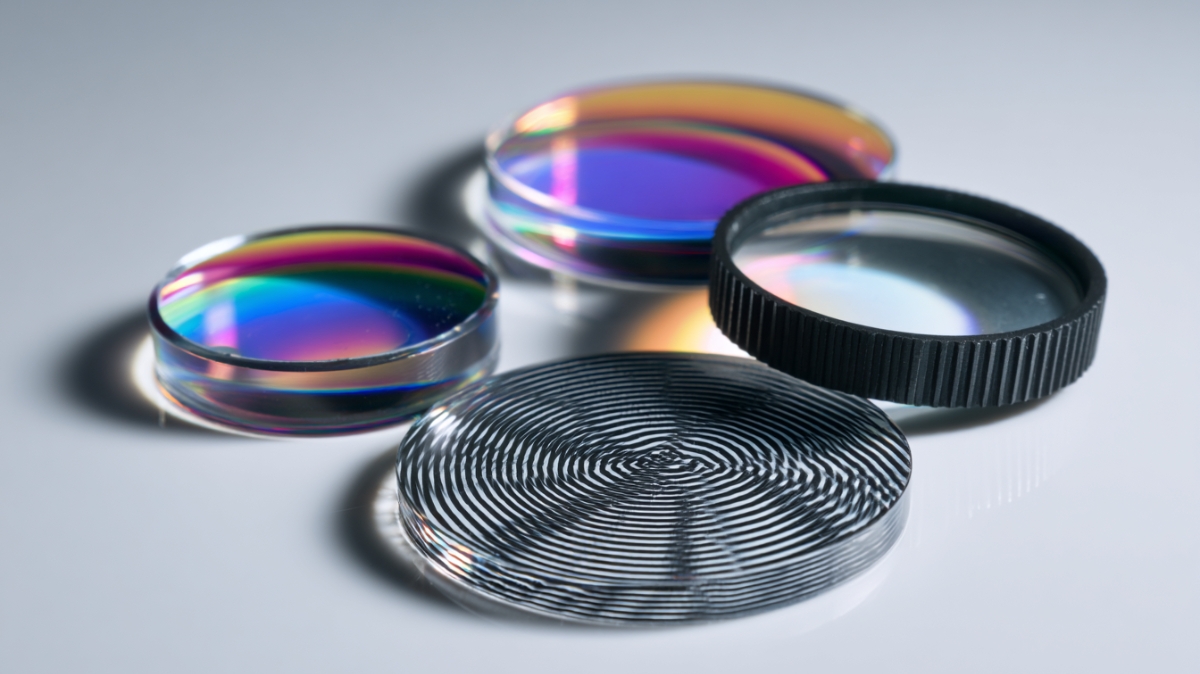

Refractive Fresnel lens

A lens that focuses or redirects light using refraction, but with the bulk “collapsed” into concentric steps (grooves). The geometry is segmented to save thickness and weight, while the optical function is still primarily refractive.

Fresnel zone plate

A diffractive focusing element made from alternating rings (“zones”) that shape the wavefront through diffraction and interference, not bulk curvature. It’s often used as a conceptual reference point because it’s easy to describe, but it’s not the same thing as the common refractive Fresnel lens.

Phase Fresnel lens (PFL)

A diffractive focusing element that uses stepped phase zones (often described as a “kinoform-like” profile) to direct more light into the desired focus than a simple zone plate. In practice, “phase Fresnel” is usually used to describe a diffractive structure designed to shape phase efficiently, not a refractive Fresnel lens.

Diffractive Optical Element (DOE)

The umbrella term. A DOE is any optic that shapes light primarily by controlling phase through micro-structure. A phase Fresnel lens is typically one type of DOE, alongside beam shapers, gratings, and other diffractive patterns.

What “Phase” Actually Means

“Phase” is the timing/position of a light wave as it travels. A phase Fresnel lens works by introducing controlled phase delays across the aperture, often via stepped surface heights, so the outgoing wavefront adds up in the direction you want (focus, pattern, etc.). Instead of bending rays with bulk curvature, you’re sculpting the wavefront.

The Two Misuses That Cause Wrong Specs

Using “Fresnel” as a catch-all for anything with rings.

Teams will call a diffractive phase structure “a Fresnel lens” because it looks stepped or zoned. That single word changes what people assume about bandwidth behavior, stray light risk, and test criteria later.

Treating “phase Fresnel” and “DOE” as competing options.

They’re often not. “DOE” is the category; “phase Fresnel” is one member of it. When that gets flipped, suppliers may quote and build fundamentally different structures under the same requirement language.

Memory Rule

Phase Fresnel is usually a DOE. “Fresnel lens” is usually refractive.

Once the labels are clear, the next step is understanding what changes in performance when you choose refraction versus diffraction.

How It Works And What It Changes

Once the terminology is clean, the decision is straightforward: are you shaping light mainly with bulk refraction, or mainly with phase structure and interference? That choice doesn’t just change thickness.

It changes what the system is sensitive to when you move from a controlled bench setup to real operating conditions.

The Core Mechanism Difference

Refractive optics redirect light through bulk geometry. Even with stepped surfaces (like a refractive Fresnel lens), the behavior stays anchored to familiar refractive assumptions.

Diffractive optics redirect light by imposing a phase profile across the aperture, so the output is formed by interference. That opens up powerful wavefront control, but it shifts the sensitivity profile.

Quick Comparison: What Changes In Practice

Decision factor | Refractive Fresnel (stepped refractive) | Phase Fresnel lens (PFL) | DOE (broader diffractive family) | What you should define upfront |

|---|---|---|---|---|

Primary function | Thickness reduction while maintaining refractive behavior | Diffractive focusing via phase zones | Diffractive phase control for focusing or patterning | What the optic must do (focus vs pattern vs redistribute) |

Bandwidth sensitivity | Often more forgiving across broader spectra | Often more wavelength-dependent (design-dependent) | Often more wavelength-dependent (design-dependent) | Wavelength band + bandwidth + source stability |

Artifact risk profile | Usually dominated by surface/stack reflections and system stray light | May introduce structured artifacts if energy distribution isn’t controlled | May introduce structured artifacts depending on pattern/order behavior | Stray light/ghost tolerance and how it will be judged |

Alignment/spacing sensitivity | Typically familiar optical tolerances | Can show “cliffs” if the system is sensitive to phase/spacing | Can be sensitive to working distance/input conditions | Assembly stack-up limits + working distance tolerance |

Best-fit evaluation metric | Imaging: MTF/contrast; Illumination: uniformity (system-dependent) | Same metric must match the job | Same metric must match the job | One pass/fail metric and where it must hold (field/plane) |

Scale-up risk tends to show up as | Drift from mechanical variation, coating/stack reflections | Unit-to-unit variation, spectral drift sensitivity, and artifacts | Input-condition drift, pattern deviation, artifacts | Verification plan: what will be measured on-part vs in-system |

The purpose of this table is not to declare a winner; it is to surface the right questions early, before an architecture is selected that cannot be validated under the system’s actual operating conditions.

Bandwidth And Chromatic Behavior: Where The Decision Gets Locked

Bandwidth is often the first constraint that turns a promising architecture into a risky one.

With many diffractive approaches, performance can shift more with wavelength than teams expect, especially if the source spectrum drifts, the system is multi-wavelength, or the design is judged across a broad band.

Even when a diffractive element is being used to balance aberrations in a system, it usually assumes a specific spectral reality. If that reality moves, the performance moves with it.

Practical takeaway: Don’t evaluate phase Fresnel or DOE options until you’ve written down the wavelength band and bandwidth you have to survive.

Stray Light, Ghosts, And Haze: What To Watch For Early

Diffractive structures can produce behaviors that don’t show up cleanly in a first-order model:

Structured artifacts: Energy appearing where it shouldn’t—secondary features, flare-like structure, or background that changes with distance or angle.

Scatter sensitivity: Micro-structure edges and surface fidelity can show up as haze or low-contrast loss, particularly in imaging and sensing paths.

System amplification: Nearby windows, baffles, coatings, and adhesives can take a small artifact and make it system-limiting.

The point isn’t that diffractive optics are “worse.” It’s that stray light should be defined and tested like a requirement, not treated as something you’ll tune out later.

Compare Using Pass/Fail Metrics, Not “Better/Worse.”

If you want a clean decision, anchor it to the metric the product is actually judged on:

Imaging: MTF/contrast targets at defined field points, plus a ghost/flare tolerance that reflects real acceptance criteria.

Illumination/projection: Uniformity and footprint/pattern tolerance at the working plane, including sensitivity to distance and alignment.

Sensing/structured light: Contrast/SNR and tolerance to background/ghost artifacts, not just “pattern visibility.”

This keeps the comparison honest: the “best” architecture is the one that meets the metric reliably in the packaged system.

Prototype Red Flags That Predict Scale-Up Pain

In early builds, these symptoms usually mean you’re close to a sensitivity limit:

Unexpected secondary structure or ghosts that appear only at certain distances or angles

Performance cliffs where small shifts in spacing or alignment create outsized changes

A design that looks strong under one source condition but falls apart when the spectrum shifts

Low-contrast haze that persists even after cleaning and basic handling controls

Unit-to-unit variation that exceeds what your assembly process should realistically produce

Those tradeoffs only matter once you map them to the job imaging, illumination, sensing, and the packaging realities around them, which is where we’ll go next.

Pick A Starting Architecture By Job Type

The fastest way to choose between a phase Fresnel approach and a broader DOE approach is to start from the job the optic has to do. In real programs, architecture gets decided less by “what’s possible” and more by what you can hold stable across bandwidth, alignment, and system variation.

Below is a practical starting point by use case. It’s not a final answer; it’s a way to pick the first architecture you prototype without wasting cycles.

Imaging: When Diffractive Helps Vs When Refractive Is The Safer Baseline

Start with a phase Fresnel/DOE-style approach when:

You’re fighting package thickness and can’t afford conventional refractive depth

The system benefits from wavefront shaping to correct or balance specific aberrations

Your operating band is controlled enough that wavelength-dependent behavior can be managed

Start with a refractive-first approach (including refractive Fresnel when thickness matters) when:

You need the most forgiving broadband behavior and stable performance across source variation

Your image quality is judged heavily on low-contrast performance (where flare/haze becomes the real limiter)

The system has limited tolerance for alignment sensitivity or “cliffs” in performance

Start-here prototype move (imaging):

Prototype a baseline refractive design (or refractive Fresnel if thickness is tight) in parallel with a phase-profile candidate only if packaging is the dominant constraint.

Compare them on the metric the product is judged on (typically MTF/contrast + stray light tolerance), not on thickness alone.

Illumination And Beam Shaping: Where DOEs Are The Default Tool

In illumination, diffractive optics often show up because you’re not trying to “form an image”, you’re trying to put energy in the right place, predictably.

Start with a DOE approach when:

You need a specific output pattern (top-hat/flat-top, line, multi-spot, custom footprint)

Uniformity at the working plane is the pass/fail driver

The system benefits from a thin element that replaces a bulk multi-element shaper

Start with a simpler redistributor (diffuser/homogenizer class solution) when:

The goal is smoothing and stability more than structured patterning

The system is sensitive to artifacts, and you’d rather trade precision for robustness

Start-here prototype move (illumination):

Define the working plane and the acceptance metric (uniformity and footprint tolerance), then prototype one DOE patterning option and one “robust” option. Validate in the real mechanical envelope, not just on an open bench.

Sensing And Structured Light: Contrast And Stray Light Decide The Architecture

Structured light and sensing systems are less forgiving than illumination because the signal often rides on contrast and background control.

Start with a diffractive/DOE approach when:

You need a controlled projected pattern and repeatability across units

The system can maintain stable input conditions and alignment

You can set and validate a stray light budget early

Start with a refractive-first approach when:

The system operates across variable conditions where robustness beats pattern precision

Low-level ghosts or haze would materially degrade detection or classification

The design can meet size constraints without relying on aggressive phase structures

Start-here prototype move (sensing):

Treat stray light like a requirement from day one. Build your prototype test to reveal ghosting and contrast loss under worst-case surfaces and angles—not just “does the pattern appear.”

Packaging And Environment: Constraints That Swing Decisions Fast

Even a “correct” optical architecture can fail if the system can’t protect or control it.

Architecture tends to swing toward refractive-first when:

The optic is exposed to contamination, abrasion risk, or aggressive cleaning

Mechanical variation and tolerance stack-ups are unavoidable

Ruggedness and stable output beat compactness

Architecture tends to swing toward phase/DOE-first when:

Space and weight are hard constraints

The system benefits from thin-phase control to replace multiple bulky elements

The design can be validated and held stable in its final packaging

Start-here prototype move (packaging):

Prototype in the real stack: mounts, windows, coatings, and nearby surfaces. The biggest surprises are almost always system interactions, not the optic alone.

After you pick a starting architecture, the next gate is simple: can it be built, scaled, and verified without surprises?

Real-World Feasibility: What Breaks At Scale, And When Hybrids Are The Smarter Answer

A diffractive design can look excellent in simulation and still fail the moment you try to productionize it. Not because the physics were wrong, but because the program treated manufacturability and verification as downstream problems.

This section is the feasibility gate: what tends to change between a lab win and a production win, what to watch for in micro-structured optics, and why hybrids are often chosen for risk control rather than performance ambition.

Prototype-To-Production Reality: What Changes When You Scale

Most programs don’t fail because the first article doesn’t work. They fail because the second, third, and hundredth units don’t behave the same way.

When you move from prototype builds to volume, teams typically face:

Input variation (source spectra, angular distribution, temperature drift) that wasn’t fully represented in bench testing

Assembly variation (tilt, spacing, clocking, bondline thickness) that introduces small wavefront errors with an outsized impact

Environmental exposure (handling, contamination, cleaning, abrasion) that changes scatter and contrast over time

Yield reality: a design that “can be made” but can’t be made consistently becomes an operations problem fast

The key shift is mindset: “works once” is development. “Works repeatedly under variation” is production.

Feature Fidelity Risks: Micro-Structures Don’t Forgive Rounding Errors

Diffractive and phase Fresnel structures depend on micro-scale geometry, doing exactly what the optical model assumes. The risks aren’t exotic; they’re practical:

Replication fidelity: Small deviations in step height, slope, or zone edge sharpness can change efficiency and artifact behavior

Edge quality: Some edges can become a source of scatter and stray structure if they’re not controlled

Surface effects: Soughness and small defects can show up as haze or contrast loss long before they show up as “visible” damage

Stack sensitivity: Once you add windows, adhesives, or protective covers, small interactions can become dominant

You don’t need to overreact to this. You just need to treat micro-structure fidelity as a requirement you can verify, not an assumption.

Coatings And Finishing: What They Help With And What They Don’t

Coatings are often introduced to improve transmission, reduce reflections, or support durability. They can be essential, but they are not a clean-up tool for a design that’s already unstable.

In practical terms:

Coatings can help manage Fresnel reflections and reduce unwanted back-reflections in a stack

They can support environmental durability depending on handling and cleaning needs

They generally do not fix fundamental issues like spectral sensitivity, order artifacts, or geometry-driven scatter if the micro-structure itself is the limiter

Treat coatings as part of the system design, not a late-stage patch.

When Hybrids Are The Best Compromise

Hybrids (refractive + diffractive) are often used because they let teams balance competing realities:

Packaging constraint + aberration control: You need thin optics, but you can’t accept the full sensitivity of a purely diffractive approach

Tolerance reality: Refractive elements can take on “stability work” while diffractive features do targeted wavefront shaping

Verification and yield: Hybrids can move the design toward something easier to manufacture and measure consistently

The point is not that hybrids are inherently better. It’s that they’re frequently the most production-friendly way to hit performance targets without living on a knife-edge.

Verification Readiness: Can You Measure What You’re Claiming?

This is the non-negotiable gate. If you can’t measure the critical attributes, you can’t control them, and you can’t scale them.

Before committing, teams should be able to answer:

What are the pass/fail metrics (MTF/contrast, uniformity/pattern accuracy, stray light limits)?

What tests prove performance in the packaged system, not just in isolation?

What attributes must be verified for the structure itself (geometry/fidelity) versus the assembled system (function)?

A design that isn’t verifiable in production is not finished; it’s a risk placeholder.

With feasibility in mind, here’s a compact verification flow you can use to confirm the architecture before you commit.

How To Verify Your Choice?

You don’t lock a phase-based optic decision by arguing about “better.” You lock it by confirming that the architecture can hit your target and survive the real variation your product will see.

This section provides a structured verification approach that can be applied during a design review or supplier discussion without requiring an extended analysis cycle.

Step 1: Define The Optical Target In Inputs, Not Adjectives

Capture the minimum set of requirements that actually constrain the choice:

Wavelength band + bandwidth (and whether the source spectrum can drift)

Working distance and field (where performance must hold, not just on-axis)

Geometry constraints: clear aperture, thickness limit, available air gaps, keep-outs

System context: is the optic inside a sealed module, near reflective surfaces, behind a window, etc.?

If your requirements are vague (“high efficiency,” “low scatter”), you won’t get a consistent design or a consistent quote.

Step 2: Define Acceptance Metrics As Pass/Fail Gates

Pick metrics the system is judged on and write them as testable requirements:

Imaging: MTF/contrast target at defined field points + an allowable stray light/ghosting level

Illumination/patterning: Uniformity at the working plane + footprint/pattern tolerance (and distance tolerance)

Sensing/structured light pattern contrast/SNR + tolerance to background and ghost artifacts

Efficiency threshold (as a requirement): Set a minimum acceptable level for the application, not a theoretical maximum

This step prevents the most common failure: a design that “works” but doesn’t meet what the product actually needs to pass.

Step 3: Confirm Feasibility Gates Before You Freeze Anything

This is where “works on the bench” can quietly become “won’t scale.”

Confirm you have agreement on:

Minimum feature fidelity required for the phase structure to behave as modeled (don’t assume it’s “fine”)

Surface quality requirements that protect your contrast/uniformity targets

Coating needs (if reflections are part of the failure mode, define the target behavior)

Alignment stack-up constraints: allowable tilt, spacing variation, clocking/orientation sensitivity

Packaging realities: contamination exposure, cleaning/handling, protection windows, abrasion risk

If you can’t define these gates, you’re not ready to lock architecture—you’re still exploring.

Step 4: Write The Verification Plan On One Page

Your verification plan should prove two things: the part is built correctly, and the system performs correctly.

What will be measured on the optic itself (structure fidelity/surface/coatings)

What will be measured in the assembled system (MTF, uniformity, pattern accuracy, stray light)

At what conditions (wavelength range, distance range, temperature range, worst-case angles)

What constitutes pass/fail, and what data format do you need for sign-off

A design that can’t be measured consistently is not a production-ready design.

Step 5: Stop Signs That Should Trigger Redesign

These are the signals that you’re on the wrong architecture or missing a constraint:

Unmeasurable requirement (“low scatter” with no metric, no test method, no threshold)

Sensitivity cliffs where small shifts cause large performance collapse

Unexplained ghosts/artifacts that persist across builds or only disappear in “perfect” bench setups

Unit-to-unit variation that can’t be explained by assembly tolerance alone

Verification mismatch: you can build the part, but you can’t prove it meets the requirement in production

If your design is now living in the zone where bandwidth assumptions, stray light, and tolerance stack-ups decide success, and you need an answer that will still be true at prototype and at volume, this is the point where a manufacturing-led optics review pays for itself.

How Apollo Supports The “Buildable And Provable” Version Of The Design

Once you’re past definitions and into pass/fail requirements, the work shifts from “can it work” to “can we build it consistently and prove it every time.”

Apollo supports that transition by:

Converting optical requirements (wavelength/bandwidth, MTF/contrast or uniformity targets, stray light limits) into a manufacturable architecture phase Fresnel/DOE, refractive Fresnel, or hybrid using DFM-style review and tolerance thinking.

Keeping prototypes production-honest so early validation reflects the realities of volume builds, not a one-off lab success.

Building verification into the plan early, what gets measured on the optic versus in the assembled system, and what pass/fail looks like in the conditions you actually operate in.

Advising on optical-grade polymer selection based on environment, cleaning/handling exposure, and durability requirements that can shift performance over time.

At this stage, what matters most is repeatability and proof: ISO 13485 alignment for regulated programs, in-house optical metrology/testing, and an end-to-end workflow under one roof (design → build → coat/assemble → verify) that reduces handoffs and variability.

If you’re weighing phase Fresnel/DOE versus refractive or hybrid options, talk with Apollo about a short architecture-and-verification review to confirm what’s buildable, measurable, and scalable before you lock the design.

Conclusion

Phase Fresnel and diffractive optics aren’t competing labels; they’re often the same conversation at different levels. The real decision is whether a phase-based approach helps your system hit its target without introducing bandwidth sensitivity, stray light behavior, or verification gaps you can’t control once you leave the bench.

If you take one thing from this comparison, let it be this: don’t lock an architecture on thickness or novelty. Lock it on the metric your product is judged on: MTF/contrast, uniformity/pattern accuracy, or sensing contrast, and make sure the design is manufacturable and measurable in the final package. That’s where many “good designs” quietly fail.

When the requirements are clear and the verification plan is real, the choice between refractive Fresnel, phase Fresnel/DOE, or a hybrid stops being philosophical. It becomes a controlled engineering decision you can scale.

FAQs

Is a phase Fresnel lens the same as a diffractive optical element (DOE)?

In most engineering usage, a phase Fresnel lens is a type of diffractive optic (i.e., it sits within the DOE family). The confusion comes from people comparing a specific DOE subtype to the broader category.

What’s the difference between a Fresnel lens and a Fresnel zone plate?

A “Fresnel lens” in products is usually refractive (a conventional lens collapsed into steps), while a Fresnel zone plate focuses primarily through diffraction/interference. They look similar (rings), but behave differently.

Why are diffractive optics more sensitive to wavelength and bandwidth?

Diffractive optics work by shaping the phase and rely on interference effects, so performance often shifts more noticeably with wavelength than purely refractive designs. That’s why you need the operating band and bandwidth defined early.

Do diffractive/phase Fresnel elements increase stray light or ghosting?

They can, depending on design details and how energy distributes into different behaviors (e.g., artifacts/structure and scatter). Treat stray light as a requirement with a test method, not as something to “tune out” later.

Can diffractive optics be made thin and lightweight compared with refractive optics?

Often yes—thin, compact form factors are a common reason teams use diffractive optics, especially in micro-optics contexts. The practical constraint is whether performance remains stable under real system variation.