Precision Polymer Microscope Objective Lenses

- ISO 13485 medical certified

- Tolerances to 0.015mm

- Biocompatible polymers

ISO 13485-2016 Certified

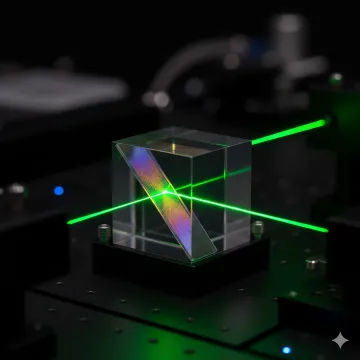

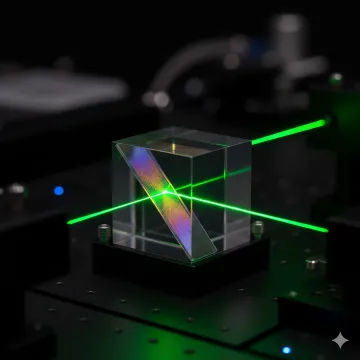

Apollo Optical Systems delivers precision polymer and diffractive optical components engineered for demanding medical device applications. Our medical optics solutions include microscope objective lenses, optical windows, beam splitters, Fresnel lenses, and aspheric elements manufactured to ISO 13485-2016 standards. From endoscopes to diagnostic equipment and medical sensing systems, our lightweight, chemically stable optics enable breakthrough healthcare innovations with exceptional performance and manufacturing precision.

Talk to our experts for custom solutions and tailored guidance.

Apply Filters

Showing 1 to 6 of 10 results

What is medical optics?

Medical optics are precision optical components used in healthcare devices like endoscopes, diagnostic equipment, and medical sensors. They manipulate light for imaging, sensing, and therapeutic applications while meeting strict biocompatibility and quality standards.

What are some medical optics examples?

What certifications are required for medical optical components?

What materials are used in medical optics manufacturing?

How are polymer optics different from glass optics for medical devices?

What manufacturing tolerances are achievable for medical optics?

What lead times should I expect for custom medical optical components?

Talk to our experts for custom solutions and tailored guidance.

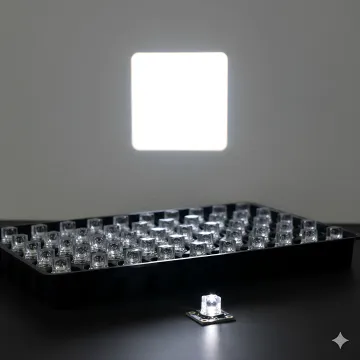

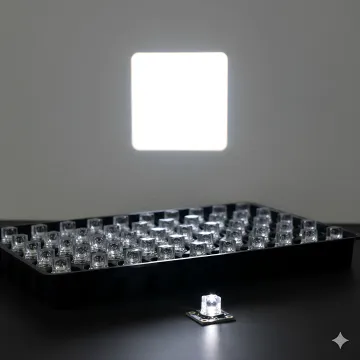

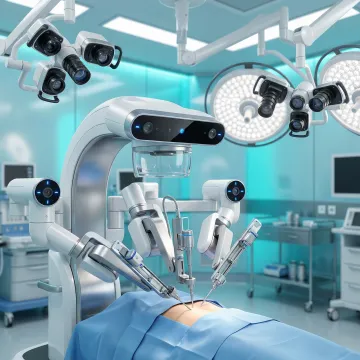

Precision polymer lenses and optical windows enable minimally invasive procedures with superior image clarity and sterilization compatibility.

High-precision microscope objectives and optical elements deliver accurate imaging for laboratory analysis and disease detection systems.

Optical components for pulse oximeters, photoplethysmography sensors, and vital sign monitors requiring biocompatible, stable materials.

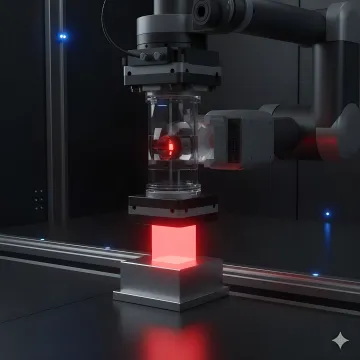

Precision optical tracking systems with fiducial markers enable accurate positioning and navigation during robotic-assisted surgery.

Talk to our experts for custom solutions and tailored guidance.

Full compliance with medical device quality management standards ensures regulatory confidence and consistent performance for healthcare applications worldwide.

Over 20 years pioneering diffractive and micro-optics technology with manufacturing tolerances down to 0.002mm for uncompromising optical performance.

From optical design and diamond turning to injection molding and coating in our 21,000 sq. ft. facility, ensuring quality, speed, and supply chain security.

Connect with our optical engineering team to discuss your healthcare device requirements. Receive expert guidance and a detailed quote within 48 hours.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com