Polymer Injection Molding

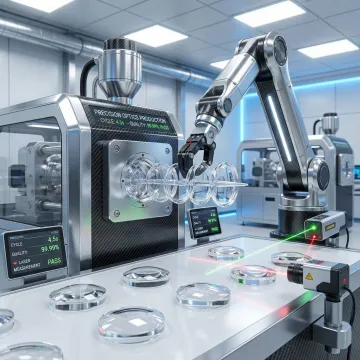

Advanced injection molding technology producing consistent, high-quality optical polymer parts with low and high-volume capabilities for complex applications.

Advanced precision plastic injection molding for optical components in Rochester's thriving optics industry. Apollo Optical Systems delivers high-quality polymer parts with exceptional dimensional accuracy and surface finishes, serving medical, aerospace, and industrial applications across New York's innovation corridor.

Comprehensive optical polymer molding solutions from design to finished assemblies.

Advanced injection molding technology producing consistent, high-quality optical polymer parts with low and high-volume capabilities for complex applications.

Precision machining of optical surfaces including aspheric, spherical, and diffractive elements with better than typical surface finishes across various polymer materials.

Complete assembly solutions from UV bonded doublets to multi-element systems, with volumes from prototypes to hundreds of thousands per month.

High-quality anti-reflective, mirror, and custom thin-film coatings specifically designed for plastic optical components across UV, visible, and NIR ranges.

Extensive in-house quality control with advanced measurement systems including CMM, interferometers, and surface profilers to ensure precision specifications.

Specialized knowledge in optical-grade polymers including acrylic, Zeonex, Zeonor, Ultem, and styrene for diverse application requirements and performance needs.

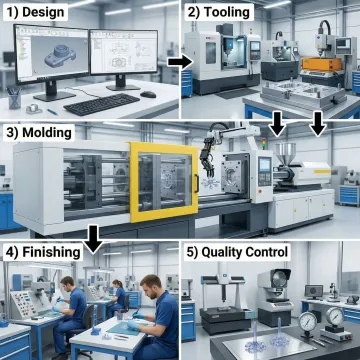

Design Consultation and Material Selection

Expert consultation on optical design requirements and material selection optimized for Rochester's industrial applications. Our team analyzes performance specifications and manufacturing constraints to recommend the best polymer solution.

Tooling Design and Fabrication

Precision Injection Molding

Diamond Turning and Finishing

Quality Verification and Testing

Delivering precision optical solutions to global leaders across multiple industries.

Over 20 years of precision optics expertise serving Rochester's advanced manufacturing community.

Complete in-house design, molding, machining, coating, and assembly services under one roof.

Legacy of innovation from University of Rochester's Institute of Optics with decades of specialized experience.

State-of-the-art equipment including diamond turning lathes and precision metrology systems in our Rochester facility.

ISO, FDA, and GMP protocols ensuring consistent performance and reliability for critical applications.

Optical engineering experts serving New York's precision manufacturing industry.

Apollo Optical Systems was born from the renowned University of Rochester's Institute of Optics, carrying forward a legacy of precision optical innovation that began in 1989. Founded through a management buyout in 2002, our Rochester-based team combines decades of research expertise with practical manufacturing experience. Operating from our 21,000 square foot facility in Rochester's technology corridor, we've built our reputation on delivering complex optical solutions that enable our clients' success. Our scientists and engineers leverage deep knowledge of optical design, precision manufacturing, and quality systems to serve customers across medical, aerospace, and industrial markets throughout New York and beyond.

What types of optical polymers can you injection mold?

We specialize in optical-grade materials including acrylic (PMMA), Zeonex, Zeonor, Ultem (PEI), and polystyrene, each selected based on specific optical and performance requirements.

What tolerances can you achieve with precision injection molding?

Do you offer prototype and low-volume production services?

Can you apply optical coatings to injection molded parts?

What quality control measures do you have in place?

How long does the tooling and setup process typically take?

Do you provide assembly services for complex optical systems?

What industries do you primarily serve?

Connect with our optical engineers for a detailed project consultation.

Institute of Optics Legacy Excellence

Certified Quality Management Systems

Medical Device Manufacturing Standards

Get expert consultation on your optical component requirements and receive a detailed project proposal.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com