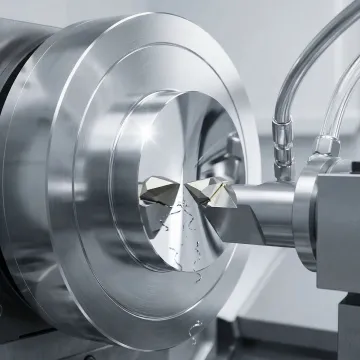

Single-Point Diamond Turning

Advanced SPDT capabilities using Precitech Nanoform 200 and Innolite IL300 lathes for components 1mm to 300mm diameter with exceptional surface finishes.

Transform your precision optical components with our state-of-the-art single-point diamond turning services. From prototype to production, we deliver exceptional surface finishes and dimensional accuracy for critical applications across medical, aerospace, and industrial sectors using advanced Precitech Nanoform and Innolite systems.

Comprehensive precision machining solutions for demanding optical applications across multiple industries and materials.

Advanced SPDT capabilities using Precitech Nanoform 200 and Innolite IL300 lathes for components 1mm to 300mm diameter with exceptional surface finishes.

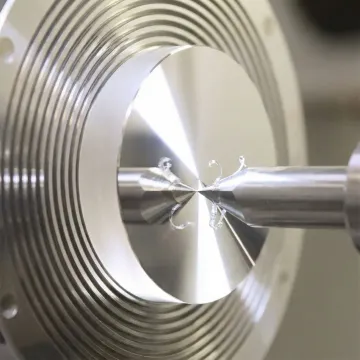

Precision machining of complex aspheric geometries achieving sub-wavelength surface figures for demanding optical performance requirements.

Specialized diamond turning for diffractive optical elements creating lightweight, high-performance alternatives to conventional refractive systems.

Expert machining across plastics, metals, and specialty optical materials including Acrylic, Zeonex, Nickel, Brass, Copper, and Aluminum.

Rapid fabrication of custom optical prototypes prior to production molding, accelerating development cycles and reducing time-to-market.

Comprehensive quality verification using advanced interferometry, CMM systems, and optical profiling to ensure specification compliance.

Our single-point diamond turning services deliver unmatched precision for optical components requiring exceptional surface quality and dimensional accuracy. With three state-of-the-art lathes and decades of expertise, we achieve industry-leading surface finishes including 13 Å RMS in Nickel and sub-wavelength figures across diverse materials for medical devices, aerospace systems, and high-performance industrial applications.

Trusted by leading organizations worldwide for mission-critical optical component manufacturing.

Industry-leading precision optics manufacturing with uncompromising quality standards.

Three precision diamond turning lathes including Precitech Nanoform 200 systems for superior capabilities.

Industry-leading surface finishes: 13 Å RMS in Nickel, 31 Å RMS in Polystyrene.

Over 20 years of precision optics experience with comprehensive end-to-end manufacturing capabilities.

Advanced metrology capabilities ensuring every component meets stringent optical and mechanical specifications.

Precision optics experts delivering exceptional results.

Apollo Optical Systems was born from the prestigious University of Rochester's Institute of Optics legacy, founded in 2002 through a management buyout that preserved decades of cutting-edge research and development expertise. Our team combines academic excellence with practical manufacturing experience, operating from our advanced 21,000 sq. ft. Rochester facility equipped with state-of-the-art diamond turning, coating, and metrology systems. We've built our reputation by transforming complex optical challenges into reliable, scalable solutions for industry leaders across medical, aerospace, and defense sectors, consistently delivering precision optics that enable breakthrough technologies and accelerate our partners' time-to-market success.

What surface finish accuracy can you achieve with diamond turning?

We achieve exceptional surface finishes including 13 Å RMS in Nickel, 31 Å RMS in Polystyrene, and typically 60-80 Å RMS with <½ wave peak-to-valley in polymers, and 30-50 Å RMS with <¼ wave peak-to-valley in metals.

What size range can you machine with your diamond turning equipment?

Which materials can be processed with single-point diamond turning?

What types of optical surfaces can you create?

Do you offer prototype development before production?

What quality verification methods do you use?

What industries do you serve with diamond turning services?

How do you ensure consistent quality across production runs?

Discuss your precision optical component requirements with our engineering experts.

Certified quality management systems

Rochester Institute of Optics legacy

Precision optics manufacturing excellence

Contact our engineering team to discuss your diamond turning requirements and receive a detailed technical proposal.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at