Metrology and Testing

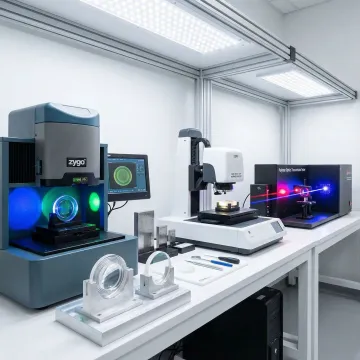

Comprehensive measurement of optical parameters using advanced equipment including interferometers, CMM systems, and surface profilers to validate component performance.

Ensure the precision and performance of your polymer optical components with Apollo's comprehensive quality assurance and testing services. Our advanced metrology capabilities, including interferometry and coordinate measuring systems, validate critical optical parameters to guarantee your products meet the highest standards for demanding applications across medical, aerospace, and industrial sectors.

Complete testing and verification solutions ensuring your polymer optical components meet exact specifications.

Comprehensive measurement of optical parameters using advanced equipment including interferometers, CMM systems, and surface profilers to validate component performance.

Detailed analysis of manufacturing tolerances ensuring optimal optical system performance through collaboration between optical and mechanical engineering teams.

Independent validation of optical designs through simulation, optimization, and prototype testing to confirm functionality before production.

Initial Design Review and Specification Analysis

We begin by thoroughly analyzing your optical component specifications and design requirements, establishing clear quality benchmarks and measurement protocols tailored to your application's critical performance parameters.

Advanced Metrology and Measurement

Tolerance Analysis and Validation

Performance Testing and Verification

Documentation and Quality Certification

Delivering precision and reliability for demanding optical applications worldwide.

The industry leader in polymer optics quality assurance and testing.

State-of-the-art metrology tools including Zygo interferometers and Zeiss CMM systems.

Over 20 years of experience in precision polymer optics testing and validation.

Complete optical and mechanical testing capabilities from prototypes to production volumes.

All testing conducted within ISO, FDA, and GMP protocols for regulatory compliance.

Expert engineers and technicians ensuring optical precision.

Apollo Optical Systems builds on a rich heritage of optical innovation dating back to 1989 as a spin-off from the University of Rochester's Institute of Optics. Founded through a management buyout in 2002, our Rochester-based facility houses 21,000 square feet of advanced manufacturing and testing capabilities. Our team of scientists and engineers combines decades of experience in precision optics with cutting-edge technology to deliver quality assurance solutions that meet the most demanding specifications. From our state-of-the-art metrology lab to our comprehensive testing protocols, we ensure every polymer optical component meets the highest standards of performance and reliability for critical applications across medical, defense, and industrial markets.

What types of optical measurements can you perform on polymer components?

We offer comprehensive optical testing including surface roughness measurement, surface figure analysis using interferometry, coordinate measurement of mechanical features, optical retardation testing, and transmission/reflection characterization across UV, visible, and NIR ranges.

What testing equipment do you use for quality assurance?

Can you perform quality testing on prototypes before production?

What surface finish accuracy can you measure on polymer optics?

Do you provide documentation for regulatory compliance?

How long does typical quality testing take?

Can you test optical assemblies or just individual components?

What industries do you serve for quality assurance testing?

Our quality assurance experts can discuss your specific testing requirements.

Certified quality management systems

Medical device testing standards

Good manufacturing practice compliance

Contact our quality assurance team to discuss your polymer optics testing requirements and get expert guidance.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at