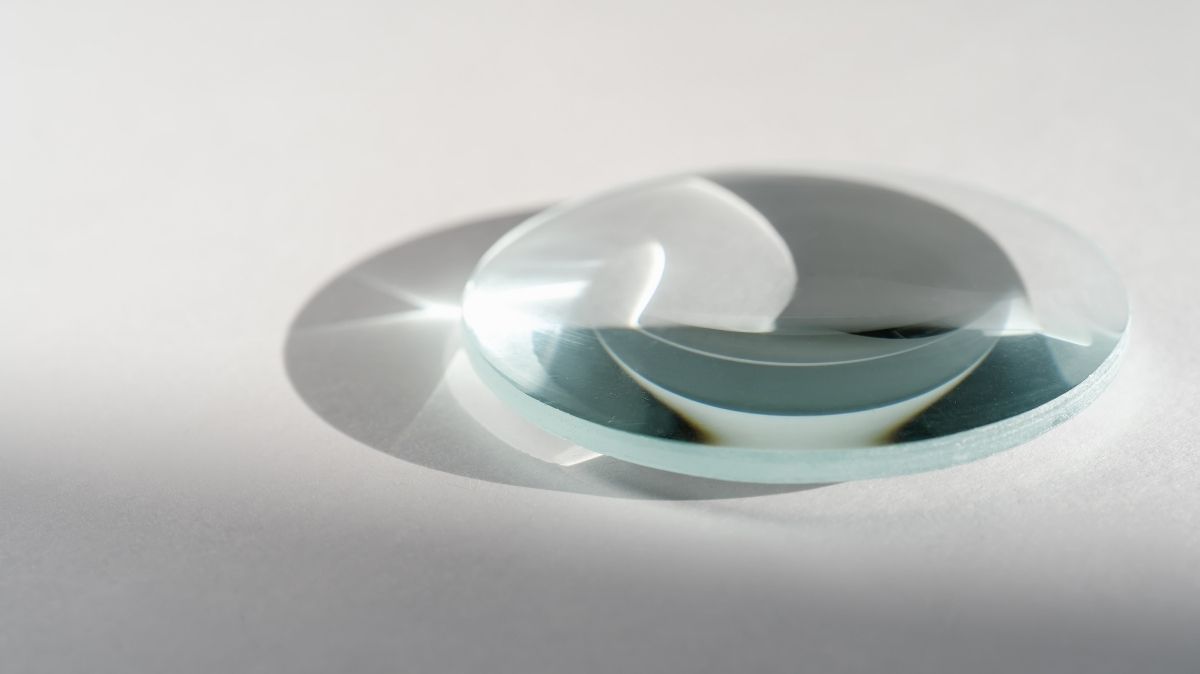

Precision optical systems rely on components that deliver exceptional performance while maintaining strict dimensional tolerances. Unlike traditional spherical lenses, which have a uniform curvature, aspheric lenses feature surfaces that vary in curvature to better control light paths. In precision optics, even small aberrations such as spherical aberration can introduce blurred focus, reduced resolution, or inconsistent sensor performance.

Custom aspheric designs address these issues by shaping the optical surface so that light rays converge at a single focal point across the entire lens aperture, yielding clearer, more accurate optical outputs. Their increasing adoption is reflected in market growth, with the global aspherical lens sector expected to reach USD 16.58 billion by 2032.

Beyond performance gains, customization enables manufacturers to optimize lens performance for specific operational requirements, reduce assembly steps, and minimize waste. In this blog, we’ll explore what custom aspheric lenses are, the materials and manufacturing techniques used to produce them, and crucial design considerations.

In a nutshell:

Custom aspheric lenses use non-spherical surface profiles to correct aberrations, improving image clarity and optical accuracy compared to traditional spherical lenses.

Different aspheric lens types, converging, diverging, plano-aspheric, diffractive, hybrid, and molded polymer, support a wide range of optical functions and system requirements.

Material choices, including optical polymers, advanced plastics, glass, infrared materials, and metals, directly influence performance, stability, and manufacturability.

Manufacturing techniques such as diamond turning, injection molding, precision tooling, micro-structuring, and optical coating balance accuracy, production volume, and cost.

Careful design, parameter control, and proper maintenance help maintain consistent performance, achieve high yields, and support long-term reliability in precision optical systems.

What Are Custom Aspheric Lenses and Why They Matter in Precision Optics?

Custom aspheric lenses are optical elements whose surfaces are defined by precise mathematical shapes rather than simple spherical curves. In practical terms, this means the geometry of the lens is engineered to correct optical imperfections that spherical lenses cannot address without using multiple elements.

Here’s why it matters:

Reduced optical aberrations: Aspheric surfaces correct spherical aberration and distortion at the lens level, improving image clarity without adding extra optical elements.

Fewer components in the optical stack: A single custom aspheric lens can replace multiple spherical lenses, reducing part count, alignment steps, and assembly time.

Improved system throughput: Better light control supports higher signal capture and more consistent optical performance across the field of view.

More compact and lightweight designs: Custom profiles allow smaller form factors, which are critical for medical devices, sensors, and space-constrained systems.

Higher manufacturing consistency at scale: Well-designed aspheric lenses support stable yields, lower scrap rates, and predictable performance in high-volume production.

Application-specific optimization: Customization allows designers to balance optical performance, material choice, and manufacturability based on real operational needs rather than theoretical designs.

Also Read: Why Aspheres Matter More Than Ever in Modern Optics

Types of Custom Aspheric Lenses

Custom aspheric lenses vary based on shape profiles, application requirements, and manufacturing processes. Understanding these types helps teams select designs that support performance targets without increasing manufacturing risk.

The most common types include:

Converging Aspheric Lenses

Converging aspheric lenses focus incoming light to a precise focal point while minimizing spherical aberration. Their surface profile offers better light control than traditional spherical lenses, especially in compact optical systems.

Ideal use case: Imaging systems where sharp focus and reduced component count are required, such as medical diagnostics and inspection optics.

Diverging Aspheric Lenses

Diverging aspheric lenses spread light in a controlled manner while maintaining optical accuracy. The aspheric surface helps manage aberrations that typically increase when light diverges at wider angles.

Ideal use case: Compact optical modules requiring controlled light dispersion, including sensor systems and handheld devices.

Plano-Aspheric Lenses

Plano-aspheric lenses have one flat surface and one aspheric surface. This design simplifies mounting and alignment while still delivering strong aberration correction on the optical side.

Ideal use case: Systems requiring compact form factors with controlled aberration correction, such as endoscopes and optical sensors.

Diffractive Aspheric Lenses

Diffractive aspheric lenses combine refractive shaping with micro-structured diffractive features. This hybrid approach helps correct chromatic aberration and improves wavelength control without adding extra lens elements.

Ideal use case: Multi-wavelength systems such as LiDAR, advanced sensors, and compact imaging devices.

Hybrid Refractive–Diffractive Aspheric Lenses

Hybrid lenses integrate both refractive and diffractive elements into a single optic. This reduces system complexity while maintaining tight optical performance requirements.

Ideal use case: High-precision medical, defense, and aerospace systems where image accuracy and system reliability are non-negotiable.

Molded Polymer Aspheric Lenses

Molded polymer aspheric lenses are designed for repeatable, high-volume production. When paired with the right material and tooling, they offer consistent optical quality with stable lead times.

Ideal use case: OEM applications requiring thousands to millions of parts with controlled tolerances and predictable production output.

Each type impacts system throughput, component count, and overall optical performance, influencing production costs and operational reliability.

Materials Used in Custom Aspheric Lens Manufacturing

Material selection directly affects optical performance, manufacturability, cost per unit, and long-term reliability. In precision optics, the right material choice supports tighter tolerances, stable yields, and predictable production outcomes across volumes.

Common materials include:

Optical-Grade Polymers

Optical-grade polymers are commonly used for custom aspheric lenses in applications where weight reduction, impact resistance, and volume scalability matter.

Acrylic (PMMA): High optical clarity with good surface finish for imaging and illumination systems.

Styrene-based polymers: Cost-focused option for controlled environments and high-volume production.

These materials support injection molding, helping reduce cost per unit while maintaining repeatable optical performance.

Advanced Optical Polymers

Advanced polymers are selected when tighter optical stability and better environmental performance are needed compared to standard plastics.

Zeonex®: Low birefringence material used in precision imaging and sensing applications.

Zeonor®: Improved thermal stability for compact optical assemblies with tight tolerances.

These polymers help improve yield consistency and reduce optical tuning during final system assembly.

Optical Glass Materials

Optical glass is used when thermal stability, wavelength coverage, and long-term dimensional control are critical.

BK7 and equivalent crown glasses: Balanced optical performance for visible-spectrum imaging systems.

Fused silica: Low thermal expansion for high-precision or high-energy optical applications.

Glass optics typically require precision grinding and polishing, impacting lead time and per-part cost.

Infrared (IR) Optical Materials

Infrared applications require materials that transmit energy beyond the visible spectrum while maintaining optical accuracy.

Germanium: High refractive index for compact thermal imaging optics.

Silicon: Suitable for near-IR applications with good mechanical strength.

Zinc Selenide (ZnSe): Broad IR transmission for aerospace and defense sensing systems.

These materials require tighter process control due to cost and handling sensitivity.

Metal Substrates for Aspheric Optics

Metal substrates are used in non-transmissive or reflective optical designs where mechanical stability is a priority.

Aluminum: Lightweight material suitable for diamond-turned reflective optics.

Nickel alloys: Used for precision-turned surfaces and replicated optical tooling.

Copper alloys: Selected for applications requiring thermal conductivity and stability.

Metal optics are often paired with reflective coatings rather than transmissive designs.

Choosing the right material early helps control scrap rates, stabilize lead times, and reduce supplier-related risk throughout the product lifecycle.

Also Read: Designing Optical Lens Systems for Performance and Scalability

Manufacturing Techniques for Custom Aspheric Lenses

Producing custom aspheric lenses requires precise control over surface geometry and material properties. Several techniques help manufacturers balance prototype speed, production volume, and optical accuracy effectively.

Single Point Diamond Turning (SPDT)

Single Point Diamond Turning is a precision machining process that creates complex aspheric surfaces directly from metal or polymer blanks. A diamond cutting tool shapes the optical surface with nanometer-level control, making it ideal for early-stage development and low-volume builds.

SPDT lets engineers validate optical performance before committing to tooling. This reduces design risk and allows teams to identify tolerance issues early, which supports higher yield once production scales.

Applications:

Optical prototyping for medical imaging systems

Design validation for defense and aerospace optics

Low-volume or custom lenses for R&D programs

Pre-production samples before injection molding

Polymer Injection Molding

Polymer injection molding is suitable for producing custom aspheric lenses at medium to high volumes. Once tooling is finalized, this process delivers consistent part quality with tight dimensional control across large production runs.

For OEMs, injection molding provides stable lead times and predictable cost per unit. When combined with proper DFM review, it reduces scrap rates and maintains consistent throughput across long production runs.

Applications:

High-volume medical device optics

Automotive sensors and ADAS components

Consumer electronics and imaging systems

Disposable and single-use optical components

Precision Mold Tooling and Replication

High-quality mold tooling is critical for producing accurate aspheric lenses through replication processes. Tool surfaces must match the aspheric geometry with extreme precision to avoid introducing optical errors during molding.

Carefully designed tooling improves process consistency and lowers scrap caused by surface defects or geometry drift, which positively affects long-term manufacturing reliability.

Applications:

Replicated polymer aspheric lenses

Long production runs require tight tolerances.

Programs focused on yield improvement

Cost-sensitive, high-volume optical components

Diffractive Micro-Structuring

Diffractive micro-structuring involves adding micro-scale surface features to an aspheric lens to control light propagation. These structures can correct chromatic aberration or reduce the number of optical elements needed in a system.

This technique is often applied when system size, weight, or optical efficiency is tightly constrained. By integrating diffractive features into the lens design, manufacturers can simplify assemblies and reduce alignment challenges.

Applications:

Compact imaging systems with limited space

LiDAR and sensing systems requiring wavelength control

Advanced medical optics with strict resolution requirements

Hybrid optical systems combining refractive and diffractive behavior

Optical Coating and Surface Finishing

Optical coatings are applied after lens fabrication to manage reflection, transmission, and environmental durability. Anti-reflective, metallic, and protective coatings improve optical performance and extend component lifespan in demanding conditions.

Proper surface finishing and coating selection maintain optical consistency over time, reduce performance drift, and help maximize system uptime.

Applications:

Medical optics requiring high transmission

Defense and aerospace systems are exposed to harsh conditions

Sensors operating across specific wavelength ranges

Optical assemblies requiring reduced glare or reflection

Selecting a manufacturing method should factor in expected volume, material, tolerance needs, and budget constraints. For example, tooling cost for molding can be high initially, but it pays off as part volumes increase.

Design Considerations for Custom Aspheric Lenses

Proper lens design plays a key role in meeting both optical performance goals and manufacturing feasibility. Design teams must consider:

Optical performance requirements: The lens should meet specific imaging or sensing needs without over-correcting or adding unnecessary complexity that affects yield.

Manufacturing feasibility: Designs should align with achievable tolerances, surface finishes, and tooling limits to control scrap and rework.

Material behavior: Thermal expansion, moisture absorption, and optical stability must match the operating environment.

System integration: Lens geometry must support stable alignment and repeatable assembly, avoiding downstream integration delays.

Optical Parameters That Influence Aspheric Lens Design

Optical parameters are critical in determining the final performance of the lens. Key parameters include:

Surface profile and curvature: Controls how light focuses and corrects across the field of view.

Focal length and numerical aperture: Influence resolution, light collection, and signal strength in imaging or sensing systems.

Wavefront error: Lower wavefront error results in sharper images and more consistent system output.

Field-dependent aberrations: Managing coma and astigmatism is essential for wide-field or off-axis applications.

Accounting for these parameters during design improves first-pass yield, reduces inspection failures, and keeps optical performance stable across production volumes.

Maintenance Tips for Custom Aspheric Lenses

Proper maintenance helps extend the life of aspheric lenses and preserves optical performance.

Key tips include:

Cleaning: Use lint-free cloths and recommended solvents to avoid surface scratches. Cleaning frequency should align with the operational environment.

Storage: Protect lenses from dust, moisture, and temperature extremes to maintain material stability.

Inspection Protocols: Periodically check for surface defects or coating wear, particularly in high-volume production or mission-critical systems.

Handling Precautions: Train personnel on safe handling to avoid drops, fingerprints, or chemical exposure that can affect lens performance.

Maintenance practices directly impact equipment uptime and reduce downtime caused by optical component failures.

How Apollo Optical Systems Supports Custom Aspheric Lens Development?

Apollo Optical Systems provides end-to-end services for custom aspheric lens projects, helping OEMs and developers reduce complexity and risk:

Here’s how we can assist you:

Collaborative Design Services: Optical and mechanical engineers work with customers to verify designs and identify manufacturability improvements.

Material Expertise: Specialized knowledge in polymers and metals allows selection of components optimized for optical clarity, impact resistance, and thermal stability.

Rapid Prototyping: SPDT enables fast iteration to validate designs before scaling to high-volume production.

Integrated Manufacturing: From polymer injection molding to coatings and assembly, Apollo provides a single-source solution that reduces supply chain risk and lead times.

Quality Assurance: Comprehensive metrology and testing ensure lenses meet strict ISO-certified tolerances, supporting consistent system performance.

Coating and Finishing: Custom AR, metallic, and evaporative coatings enhance optical performance and durability while reducing alignment issues during assembly.

By combining vertical integration with deep polymer optics expertise, Apollo Optical Systems supports faster time-to-market, reduced scrap, and improved system-level performance.

Conclusion

Custom aspheric lenses play a crucial role in modern precision optics by correcting aberrations, improving image quality, and enabling lighter, simpler optical systems. They influence key performance metrics such as system resolution, throughput, and yield, and help reduce complexity and part count within assemblies.

As optical systems advance across sectors such as medical devices, automotive sensing, and defense imaging, understanding materials, manufacturing methods, and design considerations becomes essential for achieving superior outcomes.

Apollo Optical Systems helps organizations achieve these outcomes by providing comprehensive design, manufacturing, and testing services. Connect with us today to explore how Apollo Optical Systems can support your next-generation optical systems with custom aspheric lens solutions.

FAQs

Are polymer aspheric lenses as durable as glass lenses?

Polymer aspheric lenses are durable for many applications but generally less scratch-resistant and heat-tolerant than glass. However, with hard coatings and proper material selection, they perform well in lightweight, impact-resistant, and cost-sensitive optical systems.

Can I get a prototype of a custom lens before full production?

Yes, most optical manufacturers offer prototyping for custom aspheric lenses. Prototypes allow you to validate optical performance, fit, and tolerances before committing to full-scale production, reducing design risk and ensuring the lens meets application-specific requirements.

What industries benefit most from custom aspheric lenses?

Industries such as medical devices, imaging and vision systems, consumer electronics, automotive, aerospace, defense, AR/VR, and telecommunications benefit most. Custom aspheric lenses improve image quality, reduce system size, and enhance performance in precision optical applications.

What testing and metrology methods ensure the quality of custom aspheric lenses?

Quality is ensured using interferometry, profilometry, coordinate measuring machines (CMM), surface roughness testing, and optical performance testing. These methods verify surface accuracy, form error, centration, and compliance with strict optical and mechanical specifications.

Can custom aspheric lenses be coated for specific wavelengths or environmental conditions?

Yes, custom aspheric lenses can be coated with anti-reflective, bandpass, UV, IR, scratch-resistant, or hydrophobic coatings. These coatings optimize transmission for specific wavelengths and protect lenses from humidity, temperature extremes, abrasion, and harsh environments.