Polymer Injection Molding

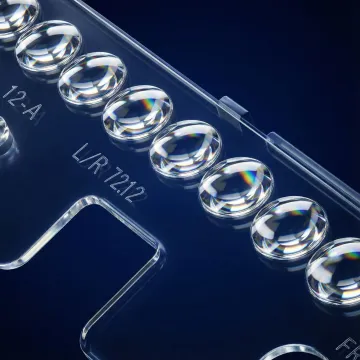

Advanced injection molding technology producing consistent, high-quality optical parts with innovative bonding processes for polymer doublets and triplets.

Transform your optical designs into high-precision polymer components with Apollo Optical Systems' advanced injection molding capabilities. From concept to production, we deliver consistent, high-quality optical parts with exceptional dimensional accuracy and surface finish quality for demanding applications across medical, aerospace, and industrial sectors.

Complete polymer optical manufacturing from design to assembly with advanced molding technology.

Advanced injection molding technology producing consistent, high-quality optical parts with innovative bonding processes for polymer doublets and triplets.

Precision machining of optical surfaces including aspheric, spherical, diffractive, and Fresnel geometries with exceptional surface finish quality.

High-quality thin-film optical coatings for plastic components including anti-reflective, mirror, filter, and beamsplitter coatings.

Comprehensive assembly capabilities from UV cemented doublets to complex multi-element optical systems with automation for high-volume production.

Extensive in-house measurement capabilities including CMM systems, interferometers, and surface profilers to ensure optical component quality.

Independent analysis and optimization of optical designs with prototype validation to ensure performance specifications before production.

Apollo Optical Systems combines advanced injection molding technology with precision diamond turning and optical coating capabilities to deliver superior polymer optical components. Our integrated manufacturing approach ensures consistent quality, optimal performance, and cost-effective production scaling from prototypes to high-volume manufacturing for demanding optical applications.

Trusted by leading companies in medical, aerospace, and industrial sectors worldwide.

Experience the Apollo advantage with proven expertise and comprehensive capabilities.

Over 20 years of precision optics experience with proven track record.

Complete manufacturing solution from design to assembly under one roof.

State-of-the-art diamond turning, coating, and metrology equipment for precision results.

Comprehensive testing and validation ensuring consistent, high-quality optical components.

Experienced optical engineers and manufacturing specialists.

Apollo Optical Systems was founded in 2002 through a management buyout, building on the legacy of Rochester Photonics Corporation which originated from the University of Rochester's Institute of Optics in 1989. Our team combines decades of research experience with practical manufacturing expertise, operating from a 21,000 sq. ft. facility in Rochester, NY. We've evolved from pioneering diffractive and micro-optics research to becoming a world leader in precision polymer optics manufacturing, serving demanding applications across medical, aerospace, and industrial markets with unwavering commitment to quality and innovation.

What materials can you injection mold for optical components?

We specialize in optical-grade polymers including Acrylic (PMMA), Zeonex, Zeonor, Ultem, and Styrene. Each material offers specific advantages for different optical applications, from cost-effective solutions to high-performance requirements.

What tolerances can you achieve with optical injection molding?

Do you provide optical coatings for injection molded parts?

What is the typical lead time for optical injection molded components?

Can you handle both prototyping and high-volume production?

What industries do you serve with optical injection molding?

Do you provide design assistance and verification services?

What quality control measures do you have in place?

Connect with our optical engineering experts for personalized consultation.

Certified quality management systems

Medical device manufacturing protocols

Good manufacturing practice standards

Contact our engineering team to discuss your precision optical component requirements and receive a detailed project proposal.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at