Polymer Injection Molding

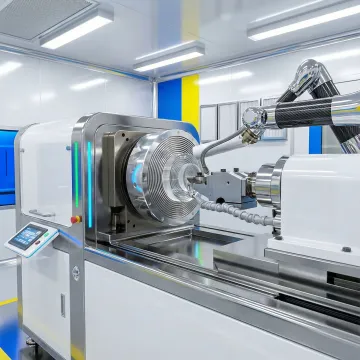

High-volume production of consistent, high-quality optical components using innovative polymer molding technology with unique bonding processes for complex assemblies.

Discover advanced precision glass molding capabilities that transform complex optical designs into high-performance components. Our comprehensive manufacturing solutions combine cutting-edge technology with proven expertise to deliver exceptional optical products for medical, aerospace, and industrial applications with unmatched precision and consistency.

Complete optical manufacturing solutions from design through production with advanced molding capabilities.

High-volume production of consistent, high-quality optical components using innovative polymer molding technology with unique bonding processes for complex assemblies.

Ultra-precision machining of optical surfaces including aspheric, diffractive, and Fresnel components with surface finishes better than 13 Å RMS in various materials.

Advanced thin-film coatings for plastic and glass components including anti-reflective, mirror, and custom solutions for UV, visible, and NIR applications.

Comprehensive assembly capabilities from UV bonded doublets to 34-element systems, handling volumes from prototypes to hundreds of thousands per month.

Extensive in-house quality control with advanced measurement systems including coordinate measuring machines, interferometers, and optical profilers for precision validation.

Complete optical and mechanical design capabilities with tolerance analysis, design verification, and manufacturing optimization using industry-leading software platforms.

Our precision glass molding services combine decades of optical expertise with state-of-the-art manufacturing capabilities. From initial design through final assembly, we deliver optical components that meet the most demanding performance requirements while maintaining cost-effectiveness and scalability for your production needs.

Delivering precision optical solutions for global leaders in medical technology and advanced systems.

Our unique combination of design and manufacturing expertise delivers unmatched precision and reliability.

Complete optical solutions from design through production under one roof.

Over 20 years of precision optics experience serving demanding applications.

State-of-the-art diamond turning, molding, and coating capabilities in 21,000 sq ft facility.

Comprehensive metrology and testing ensures consistent performance and reliability.

Optical engineering experts dedicated to precision manufacturing excellence.

Apollo Optical Systems builds on a rich heritage of optical innovation dating back to 1989 when Rochester Photonics Corporation was founded as a spin-off from the University of Rochester's Institute of Optics. After navigating industry changes and a management buyout in 2002, Apollo emerged as an independent leader in precision polymer optics. Today, our team of scientists and engineers operates from a state-of-the-art 21,000 square foot facility in Rochester, NY, continuing the legacy of bringing cutting-edge optical research into practical commercial applications. Our deep understanding of both optical theory and manufacturing realities enables us to deliver solutions that work reliably in real-world applications, helping customers accelerate time-to-market while ensuring consistent performance.

What materials can you use for precision glass molding?

We work with a wide range of optical materials including acrylic (PMMA), Zeonex, Zeonor, Ultem, styrene, and various metals like nickel, brass, copper, and aluminum for different application requirements.

What surface finishes can you achieve with single-point diamond turning?

What size range of optical components can you manufacture?

Do you provide optical coatings for plastic components?

What assembly volumes can you handle?

What quality control measures do you have in place?

Can you help with optical design and optimization?

What industries do you serve with your precision molding services?

Speak with our optical engineers about your specific application requirements.

Certified quality management systems

Medical device manufacturing protocols

Good Manufacturing Practice standards

Contact our engineering team to discuss your optical manufacturing requirements and get a detailed project quote.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com