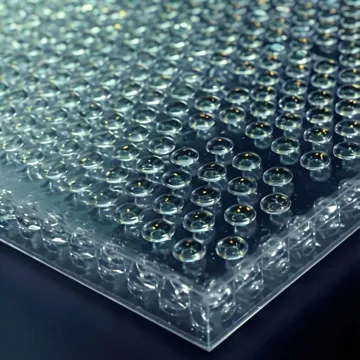

Microlens Arrays

Injection-molded microlens arrays from laser-written masters that manipulate light for diverse optical system applications.

Precision-engineered microlens arrays manufactured using state-of-the-art laser writing processes and injection molding technology. Our advanced fabrication capabilities deliver consistent, high-quality optical components that manipulate light effectively for diverse optical systems and applications across medical, defense, and industrial sectors.

Complete microlens array solutions from design to production with precision manufacturing capabilities.

Injection-molded microlens arrays from laser-written masters that manipulate light for diverse optical system applications.

Precision machining of optical surfaces including spherical, aspheric, and diffractive geometries with sub-wavelength surface finishes.

High-volume production of consistent, quality optical components using advanced polymer molding technology and bonding processes.

Anti-reflective, mirror, and custom thin-film coatings applied to plastic components using specialized polymer coating techniques.

Comprehensive quality verification using advanced interferometry, profilometry, and coordinate measuring systems for critical optical parameters.

Complete optical assembly capabilities from UV bonded doublets to complex multi-element systems with automated production scaling.

Design & Analysis

Comprehensive optical and mechanical design services using industry-leading software to optimize microlens array geometry and performance specifications for your application requirements.

Master Fabrication

Injection Molding

Coating Application

Quality Verification

Delivering precision microlens arrays for global leaders across medical, defense, and commercial applications.

Over two decades of precision optics expertise with unmatched end-to-end capabilities.

Complete in-house design, fabrication, coating, and assembly services under one roof.

20+ years specializing in precision polymer optics with University of Rochester heritage.

Advanced metrology and testing capabilities ensure consistent performance and specification compliance.

Flexible production from prototypes to high-volume manufacturing with automated assembly capabilities.

Precision optics experts with decades of experience.

Apollo Optical Systems was founded in 2002 through a management buyout, building on a rich legacy that began in 1989 with Rochester Photonics Corporation - a spin-off from the University of Rochester's prestigious Institute of Optics. Our founding team, led by Dr. G. Michael Morris, Dr. Dean Faklis, and Dr. Milton Chang, pioneered the commercialization of diffractive and micro-optics technologies. Today, we continue this tradition of innovation in our state-of-the-art 21,000 sq. ft. Rochester facility, combining academic excellence with practical manufacturing expertise to deliver world-class precision polymer optics solutions.

What materials can be used for microlens array fabrication?

We specialize in optical-grade polymers including Acrylic (PMMA), Zeonex, Zeonor, Styrene, and Ultem. Each material offers specific optical and thermal properties suited to different applications and performance requirements.

What is the typical lead time for microlens array fabrication?

Can you provide both design and manufacturing services?

What quality control measures are used during fabrication?

Do you offer coating services for microlens arrays?

What volume capabilities do you have for production?

Can you fabricate microlens arrays with custom specifications?

What industries do you typically serve with microlens arrays?

Talk to our optical engineers for a free consultation on your microlens array project.

Quality management certification standards

Medical device manufacturing standards

Good manufacturing practice standards

Contact our optical engineering team for a free consultation and custom quote tailored to your specifications.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com