Single-Point Diamond Turning

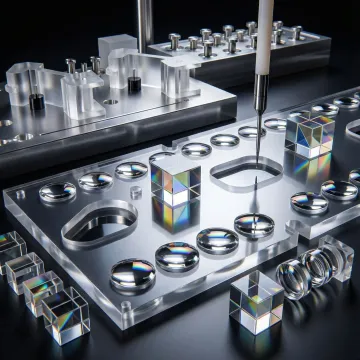

Precision machining of optical surfaces including aspheric, spherical, diffractive, and Fresnel components with sub-nanometer surface finishes across various materials.

Transform your optical designs into precision-manufactured components with Apollo Optical Systems' comprehensive manufacturing capabilities. From single-point diamond turning to injection molding and custom assembly, we deliver end-to-end optical solutions with proven expertise spanning over two decades in the industry.

Complete optical solutions from design to assembly with advanced manufacturing capabilities and precision engineering.

Precision machining of optical surfaces including aspheric, spherical, diffractive, and Fresnel components with sub-nanometer surface finishes across various materials.

High-volume production of consistent, high-quality optical components using advanced injection molding technology for various polymer materials.

Anti-reflective, mirror, filter, and beamsplitter coatings for UV, visible, and NIR ranges on both plastic and glass substrates.

Comprehensive assembly services from UV cemented doublets to complex multi-element systems with volumes from prototypes to millions per month.

Integrated optical and mechanical design capabilities with design verification, tolerance analysis, and design for manufacturing optimization.

Advanced measurement capabilities including interferometry, surface profiling, and coordinate measuring systems to ensure optical performance specifications.

Apollo Optical Systems combines over 20 years of optical manufacturing expertise with state-of-the-art facilities to deliver precision optical components and assemblies. Our comprehensive capabilities include design, manufacturing, coating, and assembly services, enabling us to accelerate your time-to-market while ensuring performance with precision and consistency across medical, defense, automotive, and industrial applications.

Delivering precision optical solutions for global partners across demanding industries.

Your trusted partner for precision optics with proven performance and innovation.

Complete optical solutions under one roof from design to final assembly.

Over 20 years of precision optical manufacturing experience since 2002.

Advanced metrology and testing capabilities ensuring consistent high-quality performance.

Cutting-edge manufacturing technologies enabling new product designs and scalable solutions.

Precision optics experts delivering innovative manufacturing solutions.

Apollo Optical Systems was born from innovation, originating as a spin-off from the University of Rochester's prestigious Institute of Optics in 1989. Founded by Dr. G. Michael Morris, Dr. Dean Faklis, and Dr. Milton Chang, our company emerged from cutting-edge research to commercialize diffractive and micro-optics technologies. After navigating industry changes and a management buyout in 2002, Apollo has established itself as a world leader in precision polymer optics. Today, we operate from our state-of-the-art 21,000 sq. ft. facility in Rochester, NY, continuing our legacy of bringing advanced optical technologies from research laboratories to real-world applications across medical, defense, automotive, and industrial sectors.

What types of optical components can Apollo manufacture?

We manufacture a wide range of optical components including aspheric and spherical lenses, diffractive optics, Fresnel lenses, microlens arrays, and custom assemblies using materials like acrylic, Zeonex, Zeonor, Ultem, and various metals.

What is single-point diamond turning and what are its advantages?

Do you provide optical coating services?

What volume capabilities do you have for production?

Can you handle both design and manufacturing?

What quality control measures do you have in place?

What industries do you serve?

How long does it typically take to complete a project?

Contact our engineering team to discuss your specific optical manufacturing requirements.

Institute of Optics Legacy

Government Technology Development

Manufacturing Excellence

Contact our precision optics experts to discuss your custom manufacturing requirements and get a detailed project quote.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at