Polymer Injection Molding

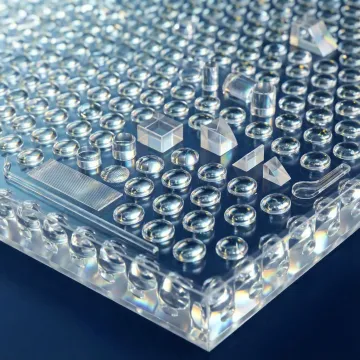

High-precision molding of optical polymers with consistent quality for low and high-volume production, featuring unique bonding processes for complex assemblies.

Transform your optical designs into reality with Apollo Optical Systems' precision polymer injection molding. Serving Monson and surrounding Massachusetts communities, we deliver consistent, high-quality molded parts with advanced bonding processes for complex optical assemblies. Our proven expertise ensures your projects meet exact specifications while accelerating time-to-market.

Complete optical manufacturing solutions from design to finished assemblies.

High-precision molding of optical polymers with consistent quality for low and high-volume production, featuring unique bonding processes for complex assemblies.

Comprehensive optical and mechanical design capabilities with integrated opto-mechanical solutions, tolerance analysis, and design for manufacturing optimization.

Complete assembly capabilities from UV cemented doublets to complex multi-element systems, with volumes from prototypes to hundreds of thousands monthly.

Precision machining of optical surfaces including aspheric, spherical, and diffractive elements with superior finishes for prototypes and production tooling.

Extensive quality control with advanced measurement systems including CMM, interferometry, and surface profiling to ensure critical optical parameters.

Specialized knowledge in optical-grade polymers including acrylic, Zeonex, Zeonor, Ultem, and styrene for diverse application requirements.

Apollo Optical Systems brings decades of expertise to Monson's growing technology sector, understanding the unique demands of Massachusetts' medical device and precision manufacturing industries. Our state-of-the-art injection molding capabilities deliver consistent, high-quality polymer optics that meet the exacting standards required for New England's advanced manufacturing environment, from prototype development to high-volume production.

Partnering with industry leaders to deliver precision optical solutions worldwide.

Your trusted partner for precision polymer injection molding in Massachusetts.

Complete in-house services from design to assembly, serving Massachusetts manufacturers with integrated solutions.

Over 20 years of precision optics experience with advanced facilities and proven track record.

ISO protocols and advanced metrology ensure consistent quality for demanding Massachusetts medical and industrial applications.

From prototype to high-volume production with cost-effective pathways to scale your operations.

Precision optics experts serving Massachusetts manufacturers.

Apollo Optical Systems was born from innovation, originating as a spin-off from the University of Rochester's Institute of Optics in 1989. After navigating industry changes and a management buyout in 2002, we've established ourselves as a leader in precision polymer optics. Our 21,000 sq. ft. Rochester facility houses advanced manufacturing capabilities, and we understand the unique requirements of Massachusetts' sophisticated manufacturing landscape, from Boston's biotech corridor to the precision manufacturing hubs throughout the Commonwealth. Our commitment to quality and innovation has made us a trusted partner for companies requiring the highest standards in optical components.

What types of polymers can you injection mold for optical applications?

We specialize in optical-grade polymers including acrylic (PMMA), Zeonex, Zeonor, Ultem, and polystyrene. Each material offers unique properties for different applications, from cost-effective solutions to high-performance requirements.

What is your typical lead time for polymer injection molding projects?

Can you handle both low and high volume production runs?

Do you provide design assistance for injection molded optical parts?

What quality control measures do you use for injection molded parts?

Can you provide assembly services for molded optical components?

What industries do you primarily serve with polymer injection molding?

How do you ensure consistent optical performance across production runs?

Contact our optical engineering team for expert consultation and project planning.

Certified quality management systems

Medical device manufacturing standards

Good manufacturing practice standards

Contact our team for expert consultation on your optical manufacturing needs. We'll provide detailed project analysis and competitive pricing.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at