Polymer Injection Molding

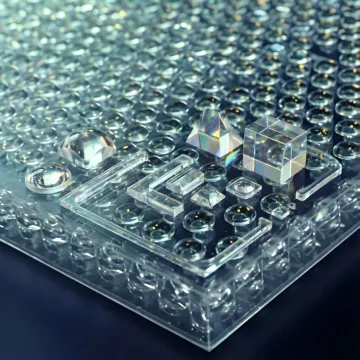

Advanced injection molding technology producing consistent, high-quality polymer parts with exceptional precision and repeatability for optical and industrial applications.

Transform your concepts into high-quality plastic components with Apollo Optical Systems' precision injection molding capabilities. Our advanced polymer processing technology delivers consistent, dimensionally accurate parts for optical, medical, and industrial applications, ensuring superior performance and reliability in every molded component.

Complete polymer processing solutions from material selection to finished components.

Advanced injection molding technology producing consistent, high-quality polymer parts with exceptional precision and repeatability for optical and industrial applications.

Specialized expertise in processing optical-grade polymers including Acrylic, Zeonex, Zeonor, Ultem, and Styrene for demanding optical applications.

Comprehensive assembly capabilities for polymer-based products, from UV cemented doublets to complex multi-element assemblies with volumes from prototypes to mass production.

Specialized DFM analysis ensuring designs are optimized for production, balancing performance requirements with manufacturing capabilities and cost-effectiveness.

Advanced in-house metrology capabilities using coordinate measuring systems, interferometers, and optical profilers to ensure precise quality control.

Comprehensive tolerance analysis services ensuring manufacturing specifications meet optical system performance requirements through engineering collaboration.

Apollo Optical Systems combines decades of polymer injection molding expertise with cutting-edge technology to deliver precision plastic components. Our advanced molding capabilities produce consistent, high-quality parts for optical, medical, and industrial applications, with specialized expertise in optical-grade polymers and complex geometries that meet the most demanding specifications.

Trusted by global leaders in medical technology and precision optics.

Leading the industry in precision polymer injection molding since 2002.

Complete in-house manufacturing from design and tooling to molding, coating, and assembly.

Over 20 years of specialized experience in precision optical polymer processing and manufacturing.

State-of-the-art injection molding equipment and metrology systems in our 21,000 sq. ft. facility.

ISO, FDA, and GMP protocols ensure consistent quality and performance in every component.

Experienced engineers and precision manufacturing specialists.

Apollo Optical Systems was born from innovation, originating as a spin-off from the University of Rochester's Institute of Optics in 1989. After navigating industry changes and a management buyout in 2002, Apollo has established itself as a world leader in precision polymer optics. Operating from our advanced 21,000 sq. ft. facility in Rochester, NY, we combine decades of research-backed expertise with cutting-edge manufacturing capabilities to serve global leaders across medical, aerospace, and industrial markets.

What materials can you injection mold?

We specialize in optical-grade polymers including Acrylic (PMMA), Zeonex, Zeonor, Ultem (PEI), and Styrene, each selected for specific optical and mechanical properties required by your application.

What tolerances can you achieve with injection molding?

Do you offer design for manufacturing services?

What volume ranges do you support?

Can you provide secondary operations and assembly?

What quality standards do you follow?

Do you provide tooling design and fabrication?

What industries do you serve?

Our engineering team is ready to discuss your precision injection molding requirements.

Quality management system certification

Medical device manufacturing standards

Good manufacturing practice compliance

Contact our engineering team to discuss your requirements and receive a detailed project proposal.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com