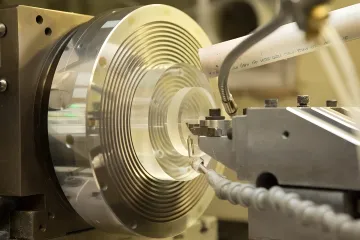

Single-Point Diamond Turning

Precision machining of optical surfaces including aspheric, diffractive, and Fresnel surfaces with exceptional surface finishes and tight tolerances.

Advanced precision plastic optical components and manufacturing services for demanding applications across medical, defense, automotive, and commercial industries. From single-point diamond turning to injection molding, we deliver exceptional optical performance with proven reliability and cost-effective scaling solutions.

Complete optical manufacturing solutions from design to assembly for high-performance polymer components.

Precision machining of optical surfaces including aspheric, diffractive, and Fresnel surfaces with exceptional surface finishes and tight tolerances.

High-volume production of consistent, high-quality optical components with innovative bonding processes for doublets and triplets.

Advanced thin-film coatings including anti-reflective, mirror, and custom solutions specifically optimized for polymer optical components.

Comprehensive optical and mechanical design services with integrated opto-mechanical solutions using industry-leading software platforms.

Expert assembly of complex optical systems from UV bonded doublets to 34-element assemblies with ISO, FDA, and Standard compliance.

Extensive quality verification using advanced interferometry, coordinate measuring systems, and optical profiling equipment.

Apollo Optical Systems combines decades of optical engineering expertise with advanced manufacturing capabilities to deliver precision polymer optical components. Our integrated approach from design through production ensures optimal performance, cost-effectiveness, and reliable scalability for your most demanding applications across medical, defense, and commercial markets.

Delivering precision optical solutions for industry leaders worldwide.

Your trusted partner in precision optics with proven capabilities and performance.

Complete in-house optical design, manufacturing, coating, and assembly services under one roof.

Over 20 years of precision optics experience with advanced diamond turning and molding capabilities.

Comprehensive metrology and testing with ISO, FDA, and Standard protocol compliance.

From prototypes to high-volume production with cost-effective pathways to scale.

Precision optics experts delivering innovative solutions.

Founded through a management buyout in 2002, Apollo Optical Systems carries forward the innovative legacy of Rochester Photonics Corporation, originally established as a University of Rochester Institute of Optics spin-off. Our team of optical engineers and manufacturing specialists operates from a state-of-the-art 21,000 sq. ft. facility in Rochester, NY, equipped with advanced single-point diamond turning, injection molding, and precision assembly capabilities. We are committed to pushing the boundaries of precision polymer optics while delivering reliable, cost-effective solutions that accelerate our clients' time-to-market and enable breakthrough product designs across medical, defense, and commercial applications.

What optical materials can you work with?

We specialize in various polymer materials offering specific optical and performance characteristics for different applications.

What surface finishes can you achieve with diamond turning?

Can you handle both prototyping and high-volume production?

What coating services do you provide?

Do you provide optical design services?

What is your typical lead time for custom projects?

Can you assist with design for manufacturing optimization?

Talk to our optical engineering experts for a free consultation.

Quality management systems compliance

Medical device manufacturing standards

Good manufacturing practice standards

Contact our optical engineering team to explore how we can deliver the precision and performance your application demands.

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com

For immediate assistance, feel free to give us a direct call at +1 585-272-6170 You can also send us a quick email at info@apollooptical.com